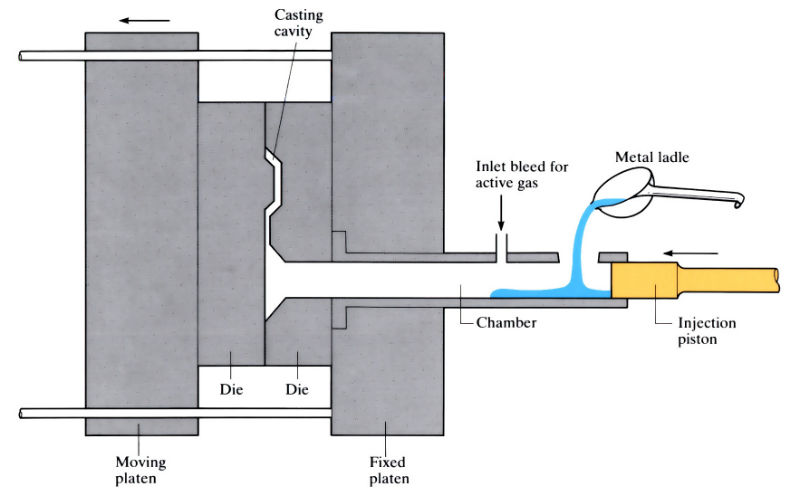

Conventional high pressure die casting uses air at 10–20 MPa to fill the mould rapidly, leading to air entrapment (porosity) in the casting, with a reduction in mechanical properties, weldability, ease of heat treatment and pressure soundness. Low pressure die casting and the "Acurad" process overcome porosity to some extent, but at the expense of accuracy, complexity and production rate. Pore-free die casting removes nearly all porosity by filling the die cavity with an "active gas" (usually oxygen) which combines chemically with the molten metal to form a finely dispersed solid.

Manufacture:

- Uses conventional high pressure die casting machines with a special process control system to supply the active gas to the specially designed dies.

- Pore-free casting (PF) allows a reduction in casting pressure, and hence machine size, compared with high pressure die casting, enabling same-sized components with similar properties to be produced at lower pressures, with a corresponding increase in die life.

- Production rates are less than for high pressure die casting due to the filling of the die with the active gas before each shot. Nevertheless production rates are still comparatively high (≃ 40 shots h–1).

- The PF process has many advantages over other competitive processes, as shown below.

- Process currently used to produce a wide range of products for the automotive industry, such as wheels, master cylinders, rack-and-pinion housings and hydraulic disc-brake calipers.

| Characteristic | Permanent mould casting | High pressure die casting | Acurad | Pore-free |

| Yield | Good | Bad | Good | Good |

| Heat treatment | Good | Bad | Average | Good |

| Weldability | Good | Bad | Good | Good |

| Internal defects | Good | Bad | Good | Good |

| Dimensional accuracy | Average |

Good |

Good | Good |

| Complex shapes | Bad |

Good |

Bad |

Good |

|

Wall thickness: Thin |

Bad |

Good |

Bad |

Good |

| Wall thickness: Thick | Good | Bad | Good | Average |

| As-cast surface | Average |

Good |

Good | Good |

| Separation of runner and riser | Bad |

Good |

Bad | Good |

| Productivity | Bad |

Good |

Good | Good |

| Cost of die and equipment | Good | Bad | Bad | Bad |

Materials:

- At present used only on aluminium die casting alloys, but there appears to be no reason why the process could not be applied to zinc-based die casting alloys.

- Aluminium alloys contain 0.1–0.2 wt% of very fine alumina (Al2O3) particles of <1 µm, which give a fine grain structure and improve tensile and fatigue properties.

- Tensile properties of pore-free castings approach those of wrought materials.

- The mechanical properties of PF die castings are not so sensitive to impurities as ordinary die castings, enabling the cheaper materials to be used.

- Lack of porosity gives good weldability and enables castings to be used at higher temperatures, since the distortion and blistering due to the pores in ordinary die castings is eliminated.

Design:

- Similar components to those produced by high pressure die casting, although lack of porosity and increased mechanical properties often allow designs to be altered to give a weight saving and less material cost.

- Lack of porosity enables welding to be carried out using conventional argon aluminium welding equipment. This means large products can be made by welding together several component die castings.

- Lack of porosity means casting around inserts causes fewer problems than with high pressure die casting.

See Also: High pressure die casting, Acurad process, Hot forging (closed die) and Sand casting.

This article is a part of Manupedia, a collection of information about some of the processes used to convert materials into useful objects.

Rate and Review

Rate this article

Review this article

Log into OpenLearn to leave reviews and join in the conversation.

Article reviews