2.1 Crystalline silicon PV

The most efficient silicon solar cells are made from extremely pure monocrystalline silicon – that is, silicon with a single, continuous crystal lattice structure with virtually no defects or impurities.

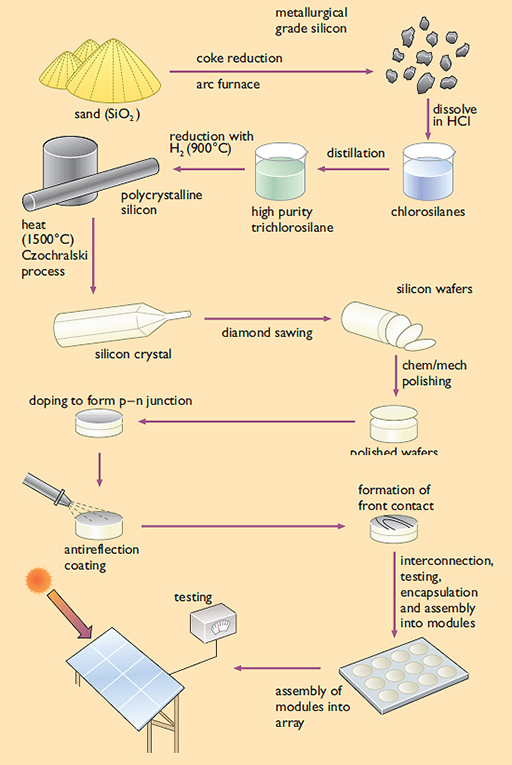

Monocrystalline silicon is usually grown from a small seed crystal that is slowly pulled out of a molten mass of polycrystalline silicon, in the sophisticated ‘Czochralksi’ process developed originally for the electronics industry. You can see the overall process of monocrystalline PV cell and module production in Figure 3

Polycrystalline silicon essentially consists of small grains of monocrystalline silicon. Solar cell wafers can be made directly from polycrystalline silicon in various ways, which include the controlled casting of molten polycrystalline silicon into cube-shaped ingots, which are then cut into thin, square wafers and fabricated into complete cells in the same way as monocrystalline cells. Polycrystalline PV cells are easier and cheaper to manufacture than their monocrystalline counterparts, but are less efficient.

Commercially available polycrystalline PV modules (sometimes called ‘multicrystalline’ or ‘semicrystalline’), typically attain energy conversion efficiencies of around 20%, whereas monocrystalline module efficiencies can exceed 24%.

Activity 1

How much voltage does a typical silicon PV cell produce?

Answer

A typical silicon PV cell produces around 0.5 volts. These cells are usually combined into PV modules incorporating 60–72 PV cells connected in a series- parallel combination. They are normally around 1.4 to 1.7 m2 in area (though some are larger), and have a peak power output of some 120–300 watts, depending on the design and technology.