5.1 Sewage treatment processes

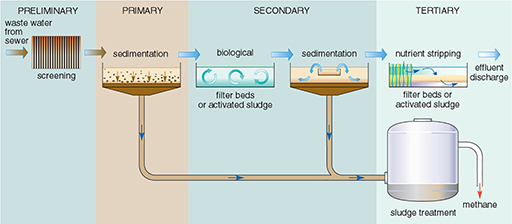

The processes at a sewage treatment works are relatively simple, and mostly mimic natural processes. Not all treatment works use all the treatment stages — some plants provide only preliminary and primary treatment, and tertiary treatment is relatively rare. The processes are summarised in Figure 18 and amplified below:

Preliminary treatment: This is the mechanical removal of coarse and fine solid material. The sewage passes through screens, which trap pieces of wood, rags, wire, etc. The extracted material is usually buried, but it may be burned.

Primary treatment: The sewage then flows slowly through grit tanks, where particles of sand or grit settle out. Fine particles still remain suspended in the sewage, so it is passed to large primary sedimentation tanks where most of the remaining particles settle out to form a sludge. Primary treatment removes about 60-70% of suspended solids (Table 6). The liquid leaving the primary sedimentation tanks still contains very fine solids and dissolved matter, so secondary treatment is usually required.

Figure 18 Flow diagram of the stages of treatment in a sewage treatment plant.

Figure 18 Flow diagram of the stages of treatment in a sewage treatment plant.

| Constituent | Primary | Secondary | Tertiary |

| suspended solids | 60-70 | 80-95 | 90-95 |

| BOD | 20-40 | 70-90 | >95 |

| phosphorus | 10-30 | 20-40 | 85-97 |

| nitrogen | 10-20 | 20-40 | 20-40 |

| E. coli bacteria | 60-90 | 90-99 | >99 |

| viruses | 30-70 | 90-99 | >99 |

| cadmium and zinc | 5-20 | 20-40 | 40-60 |

| copper, lead and chromium | 40-60 | 70-90 | 80-89 |

Secondary treatment: This is a biological process, involving the oxidation of dissolved organic material by micro-organisms to decompose the organic compounds, a process similar to that taking place in rivers, the soil, or filter beds in water treatment works. The process is speeded up by increasing the amount of oxygen available, which can be done by two possible methods:

Filter beds: The liquid is sprayed slowly over beds of broken stones, gravel, coke or plastic (Figure 19), which provide a large surface area for oxidation, and the micro-organisms (mainly bacteria) living within the filter bed break down the organic matter. The liquid that collects at the base of the filter bed contains some waste products from the filter organisms. These are separated from the effluent in secondary sedimentation tanks, producing more sludge. Filter beds need very little supervision, but take up a lot of land.

Figure 19 Filter beds at a waste water treatment plant. Rotating arms spray sewage onto the circular beds, where it is broken down by bacteria.

Figure 19 Filter beds at a waste water treatment plant. Rotating arms spray sewage onto the circular beds, where it is broken down by bacteria.Activated sludge: A sludge containing bacteria and other organisms is mixed with the liquid, and the whole mixture is agitated by paddles or has compressed air bubbles through it, to keep it well oxygenated. This process lasts about 10 hours, after which the mixture flows to sedimentation tanks where the sludge settles out from the effluent.

Secondary treatment in addition to primary treatment removes about 70-90% of the BOD in the sewage (Table 6), so the effluent is usually sufficiently purified to be discharged to a river, lake or the sea.

Tertiary treatment: Primary and secondary treatment remove only 20-40% of the phosphorus and nitrogen, and about half of the toxic compounds. If it is necessary to reduce plant nutrients or toxic compounds beyond these levels tertiary treatment is required, but this is very expensive and not commonly used. Various types of tertiary treatment exist, e.g. nutrient stripping, disinfection by UV light or filter membranes. Where land area is available, allowing the effluent to flow through constructed ponds or lagoons is another option.