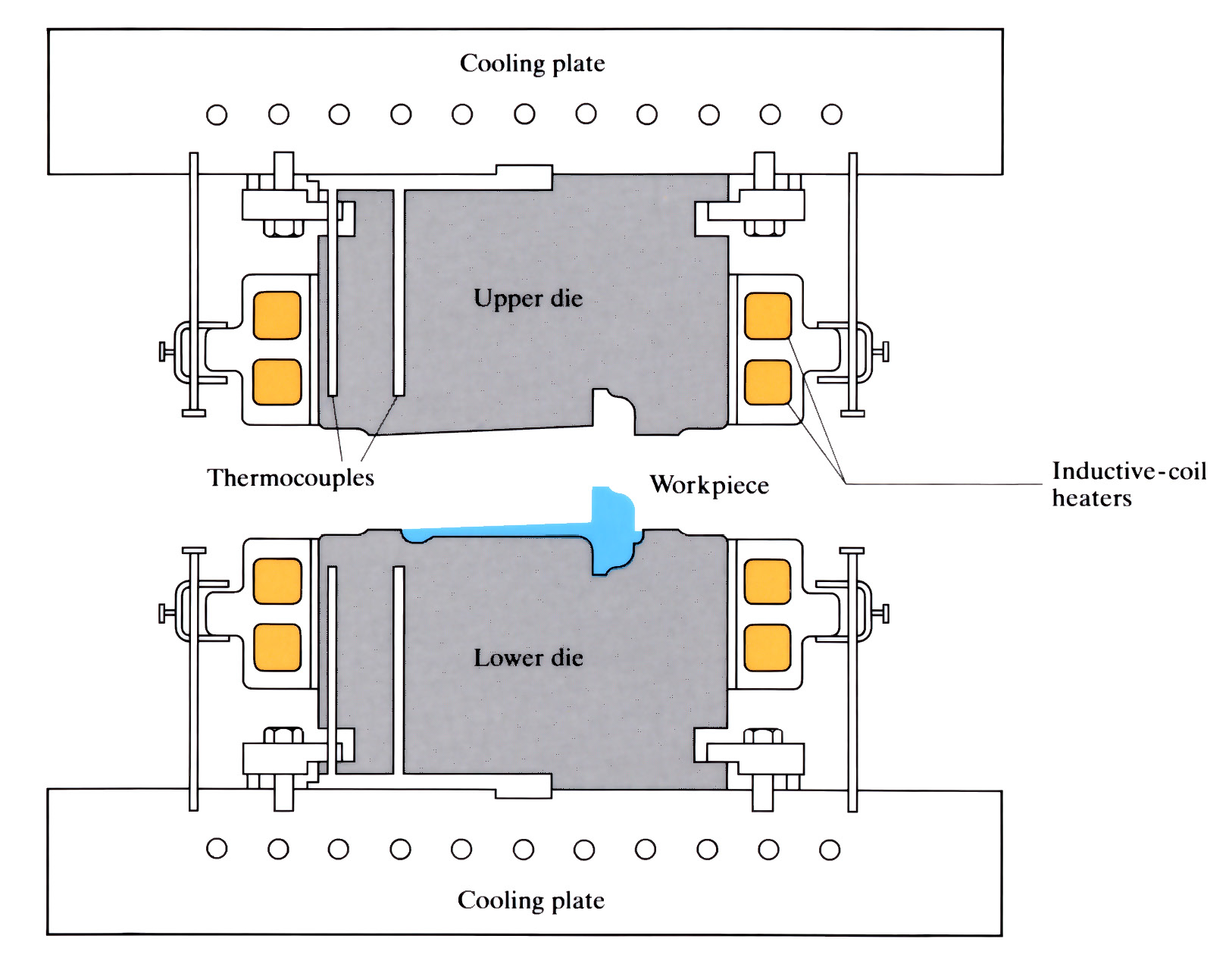

- Die set is pre-heated to 100°C below the forging temperature using cartridge or induction heaters (e.g. ~ 750°C for titanium alloys).

- Dies are sprayed with die lubricant or parting agents. No lubricant is used for Ti alloys (surface oxides are used as a tenacious oxide).

- Preform is heated to the forging temperature, placed between the heated dies and forged at slow rates of 10-3–10-2 s-1.

- Component is removed from the dies after forging. It is then cleaned, minimal machining such as drilling holes is done, then finally it is heat treated.

Manufacture:

- Slower than conventional forging (10–103 s-1) due to slower strain rate required (10-2–10-3 s-1).

- Die sets are expensive due to the use of expensive high temperature materials, such as Cronite (Fe-25Ni-20Cr) or IN100 nickel-based alloy. Die wear is minimised by optimisation of isothermal forging temperature.

- Forging loads are less than conventional forging (titanium alloy: conventional 500–1200 N mm-2, isothermal 80–120 N mm-2).

- Forging and die costs are higher than for conventional forging, but the savings in material and machining costs can lead to 20% overall cost saving for the production of titanium fan blades.

- Mainly used for the production of aerospace and gas turbine components, such as fan blades, hollow stator blades and gas turbine engine casings.

Materials:

- All materials that can be conventionally forged can also be isothermally forged.

- Mainly used on aluminium alloys, titanium alloys, iron-12% chromium alloys and nickel-based superalloys.

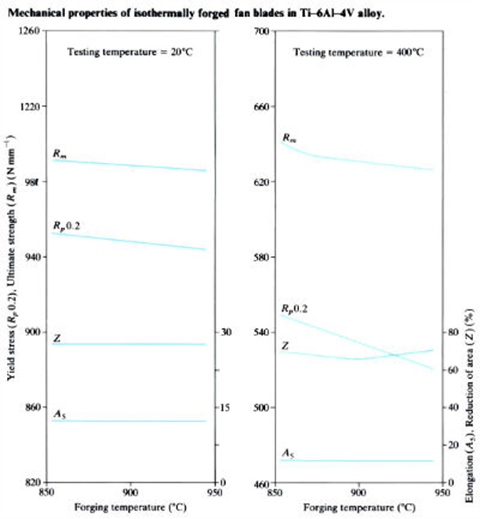

- Mechanical properties of isothermally forged alloys are similar to conventionally forged properties.

- Fine grain sizes and minimal grain flow can be achieved.

Design:

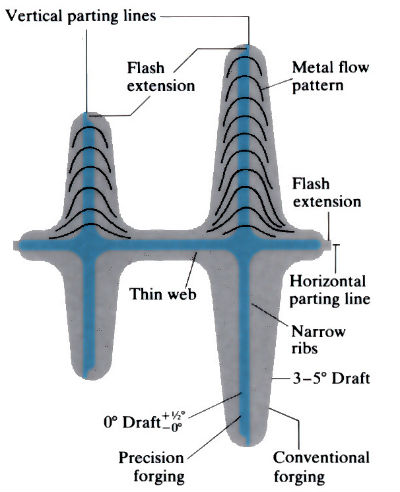

- Isothermal forgings are subject to some design constraints: no undercuts or side pockets.

- Process is particularly suitable for producing thin profiles with little or no draft angles, as shown below.

- Tolerances approach those for machined parts. Thickness tolerances are slightly greater, i.e. ±0.75 mm. In aluminium alloys, edge radii are 1.5 ± 0.45 mm, fillet radii 3.25 ± 0.97 mm and surface finishes of 3.2 μm Ra are possible.

- Little or no machining is required except for holes.

- Isothermal forgings have better dimensional accuracy than conventional forgings. This leads to better accuracy for assembly: e.g. fan blades do not need truing, so there is less twist. Turbine engine casings can be produced with no springback, so they can be accurately joined by NC laser welding.

See Also: Hot forging (closed die), Superplastic forming, Squeeze forming and Investment casting.

This article is a part of Manupedia, a collection of information about some of the processes used to convert materials into useful objects.

Rate and Review

Rate this article

Review this article

Log into OpenLearn to leave reviews and join in the conversation.

Article reviews