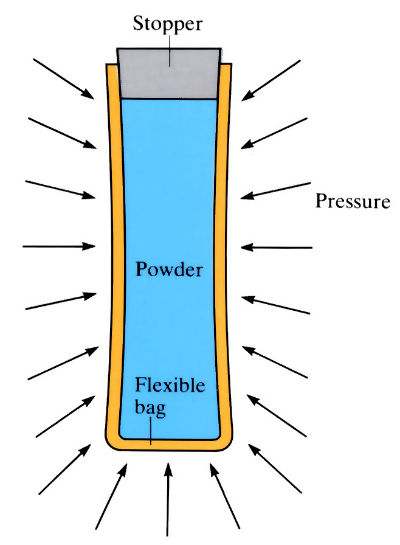

Principle of isostatic pressing

1. Powder is placed and sealed in flexible mould such as polyurethane and is then subjected to a uniform hydrostatic pressure.

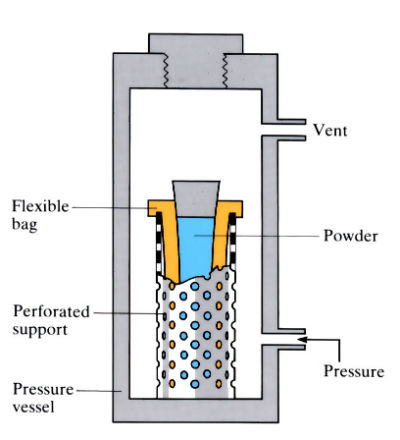

2. Wet-bag technique. Flexible bag containging the powder is submerged in the pressure vessel containing the pressurising fluid, such as soluble oil.

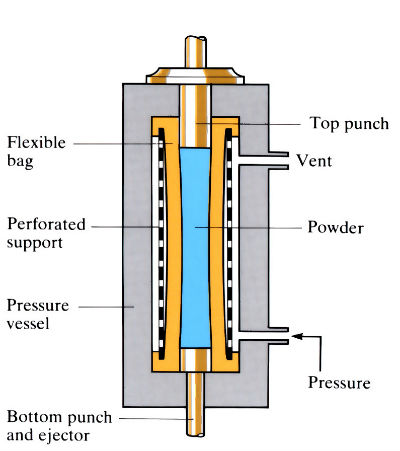

3. Dry-bag technique. Flexible bag is "fixed" in the pressure vessel and powder can be loaded without bag having to leave the vessel.

Manufacture:

- Cold isostatic pressing (CIP) compacts powders to achieve a uniform density in the compact.

- No lubricant has to be added to the powder, which results in green strengths 10 times greater than cold compaction in metal dies with added lubricant, and no lubricant burn-off stage is required during sintering.

- Wet-bag technique. Flexible bag filled with powder is submerged in the pressure vessel containing the pressurised fluid (such as soluble oil) and pressure is applied to the fluid from an intensifier/pumping system. Depending on the size of the chamber, several bags can be loaded into the space available. This is a batch process and compaction cycle time varies between 2 and 5 min.

- Dry-bag technique. Flexible bag is “fixed” in the pressure vessel and powder is loaded into the bag(s) without the bag having to leave the pressure vessel. The dry-bag technique lends itself to more automation of bag-filling, compaction and compact removal. Multiple cavities can be used on dry-bag up to rates of production of 1500 parts h-1.

Materials:

- All powders can be cold isostatically compacted, including ceramics such as alumina spark-plug shells and silicon nitride components.

- Tungsten powders are cold isostatic pressed (CIP) into a variety of shapes.

- High alloy ferrous billets are CIP before hot isostatic pressing (HIP).

- A wide range of ceramics are CIP including alumina (Al2O3), silicon nitride (Si3N4), silicon carbide (SiC) and sialons (Si-Al-O-N).

Design:

- Cold isostatic pressing can produce components and preforms of much greater size and complexity than uniaxial die compaction.

- Components with longer length/diameter ratios can be produced with uniform density along their complete length.

- Compacts have higher densities and green strengths (x10) compared with their die compacted counterparts.

- Complex undercut and threaded shapes can be produced with CIP.

- Ceramic billets are machined before final hot pressing, i.e. HIP or reaction bonding, e.g. silicon nitride.

See Also: Hot isostatic pressing, Cold pressing and sintering of powders, Slip-casting and Pressureless sintering.

This article is a part of Manupedia, a collection of information about some of the processes used to convert materials into useful objects.

Rate and Review

Rate this article

Review this article

Log into OpenLearn to leave reviews and join in the conversation.

Article reviews