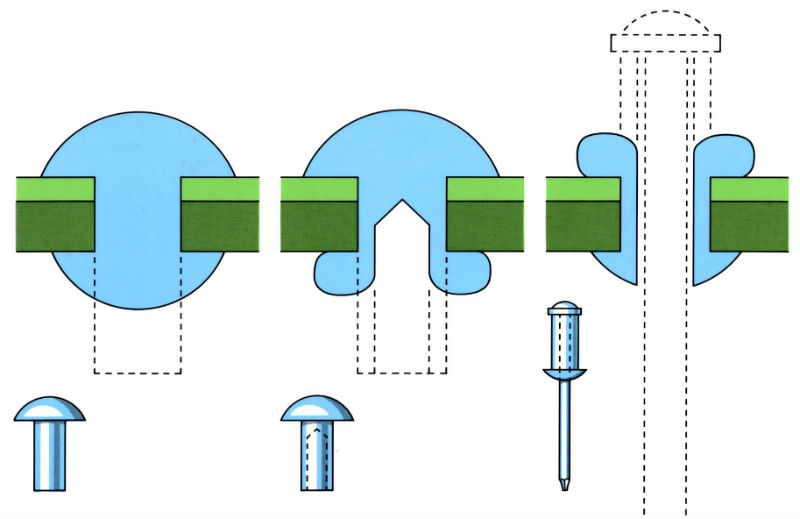

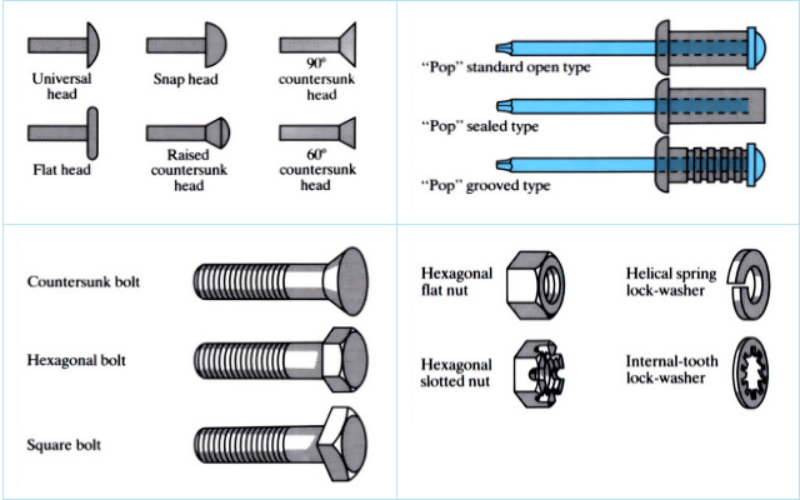

Rivet types

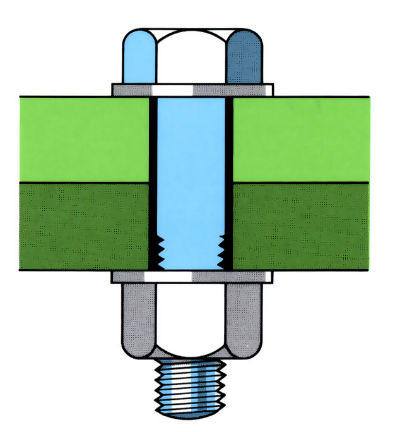

Assembled bolted joint

Manufacture:

Nuts and bolts

- Used primarily for structural, load-carrying joints, which are to be demountable for inspection, repair and maintenance.

- Fine threads should be used in preference to coarse threads where high strength is required.

Rivets

- Used primarily for “low strength” joints that cannot easily be disassembled for maintenance, inspection or repair.

- In addition to their basic function as fasteners, rivets can be used as pivot shafts, spacers, electrical contacts, stops and inserts.

- Lower cost than comparable threaded fasteners.

- Components can be assembled using high speed automatic riveting machines, at the rate of over 1000 assemblies per hour.

Materials:

Nuts and bolts

- A wide variety of metallic and non-metallic materials from complex precipitation-hardening alloys to thermoplastics.

- Choice of material depends on components being joined, type and magnitude of load, temperature and environment.

- Despite the large range of materials available, most nuts and bolts are made by hot or cold forging of mild or carbon steel.

- Temperature range of bolts is usually limited by stress relaxation.

- Typical steels for fasteners under different temperature ranges:

| Temperature range (˚C) | Recommended material | |

| Bolts | Nuts | |

|

-20 to 300 |

Mild or carbon steel |

Mild carbon steel |

|

-100 to 400 |

1% chromium-molybdenum steel |

Carbon-molybdenum steel |

|

0 to 450 |

1% chromium-molybdenum steel (higher Mo) |

Carbon steel |

|

0 to 500 |

12% chromium steel |

Carbon-molybdenum steel |

|

0 to 520 |

1% chromium-molybdenum-vanadium steel |

Carbon-molybdenum steel |

|

0 to 565 |

1% chromium-molybdenum-vanadium boron steel |

1% chromium-molybdenum steel |

|

-250 to 575 |

18/8 type chromium-nickel steel |

1% chromium-molybdenum steel |

|

-250 to 600 |

Chromium-nickel-molybdenum steel |

1% chromium-molybdenum steel |

|

-250 to 650 |

Nickel-chromium steel |

1% chromium-molybdenum steel |

| -250 to 750 | Nimonics | 1% chromium-molybdenum steel |

Rivets

- A wide variety of metallic materials depending on components to be joined, type and magnitude of load, temperature and environment.

- The majority of rivets are made from steel, aluminium or brass, although a wide variety of other materials are available, such as high-alloy and stainless steels, and precious metals.

Design:

- There is a wide range of rivet, bolt, nut and washer designs. A selection is shown below.

See Also: Brazing, Soldering, Adhesive bonding, Diffusion bonding and Injected metal assembly.

This article is a part of Manupedia, a collection of information about some of the processes used to convert materials into useful objects.

Rate and Review

Rate this article

Review this article

Log into OpenLearn to leave reviews and join in the conversation.

Article reviews