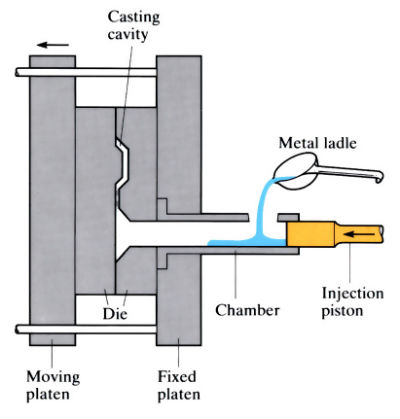

"Cold-chamber" high pressure die casting

Molten metal is poured into a cold shot chamber. A high pressure single plunger forces metal into the single or multi-die cavity.

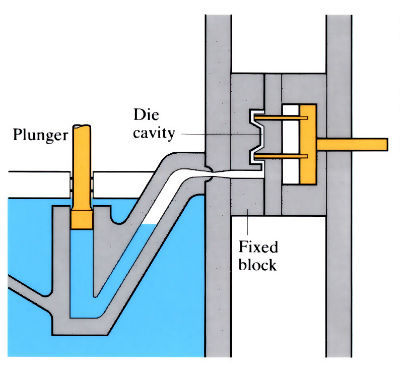

"Hot-chamber" high pressure die casting

A gooseneck hot chamber is submerged in a pot of molten metal. Metal is injected directly from the pot via the gooseneck.

Manufacture:

- High pressure die casting can be divided into “cold-chamber” and “hot-chamber” processes.

- In the cold-chamber process, molten metal is metered into a cold chamber for each machine cycle (or shot).

- The molten metal is then forced by a single plunger through a narrow feeder channel (or gate), into the die cavity itself, by the application of pressures from 7 to 207 MPa.

- The metal solidifies rapidly because the die is water-cooled within a fraction of a second.

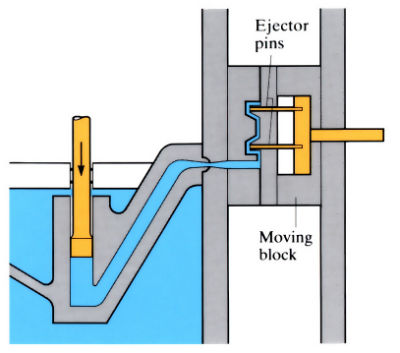

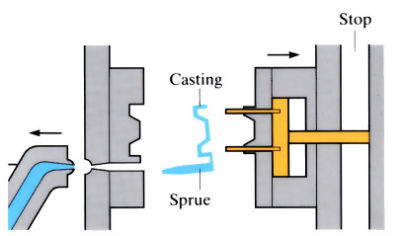

- Upon solidification, the dies are opened and the casting is removed using ejector pins.

- Most of the castings will have flash where the two die halves come together. This is usually removed in a trimming die.

- The high cost of dies (up to £250,000) and the capital cost of machines (£175,000–£350,000) limit this process to high volume production of components.

- Hot-chamber die casting is limited to the low melting point magnesium and zinc alloys, where contamination by iron will be less extensive. A gooseneck shot sleeve is submerged in a heated pot of molten melt. A plunger descends and forces the molten metal into the die. As the piston retracts, the cylinder is filled with metal.

Materials:

- High pressure die casting is restricted to the lower melting point alloys.

- The bulk of die casting is carried out in zinc-, magnesium- and aluminium-based alloys.

- The most popular zinc-based alloys (known as Mazak) contain 3.8–4.3% aluminium and 0.10–1.25 wt% copper, with tensile strengths of 293–355 MPa, and elongations of 3–4%. Zinc alloys have a higher impact strength than die cast aluminium alloys.

- There are six main aluminium die casting alloys used in the UK. All contain 4–13 wt% silicon, which is used to promote good castability. The most common alloy is LM6-M (BS 1490), which contains 10–13% silicon, and has a tensile strength of 280 MPa and an elongation of 2–5%.

- Strict melting practice is required with magnesium-based alloys, which are mainly used on hot-chamber machines. The most popular alloy contains 9–10% aluminium and 1% zinc, achieves a tensile strength of 215 MPa and an elongation of 2%.

- The degree of retained porosity in the die casting affects the properties of the product.

Design:

- High pressure die castings can provide thinner cross sections than any other casting process. Wall thicknesses as thin as 0.38 mm can be achieved in small aluminium components. For large components, wall thicknesses range from 2.7 to 4.5 mm.

- Die size is only limited by the capacity of the machine. Most die castings are limited to about 34 kg (zinc), 30 kg (aluminium) and 20 kg (magnesium).

- Close tolerances are possible.

- Surface finish depends on the quality of finish on the dies. Parts made from new or repolished dies may have surface finishes of 0.6 µm. This high quality finish enables other coatings, such as chrome plating and painting, to be applied directly.

See Also: Injection moulding, Acurad process, Pore-free die casting and Gravity die casting.

This article is a part of Manupedia, a collection of information about some of the processes used to convert materials into useful objects.

Rate and Review

Rate this article

Review this article

Log into OpenLearn to leave reviews and join in the conversation.

Article reviews