Manufacture:

The main heat sources are as follows:

- Lasers are the most common, providing a focused heat source down to fractions of a millimetre. They require shielding from oxidation but do not require a vacuum.

- Electron beam systems are less common, providing the smallest spot size and best beam definition. However, the high attenuation of electrons by gases requires the process to be carried out in a vacuum.

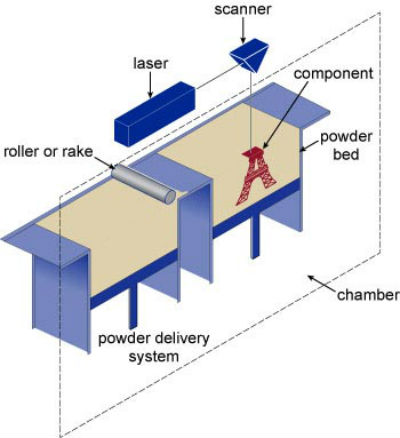

Supplying material as a powder bed allows very fine features to be produced using SLM and little material is wasted.

- Compared to DMD, scanning is restricted to two directions. This limits the flexibility in design.

- The size of the component is limited to the size of the powder bed. This is commonly less than 1 m x 1 m.

- Best suited to producing geometrically accurate high-value components.

Materials:

Proven for a wide range of materials, however many exhibit properties that are poorer than those of wrought material of the same chemical composition. Development is popular with high-cost materials due to the reduction in wastage compared to subtractive manufacturing. Materials such as (limitations in brackets):

- Nickel-based super alloys (rapid cooling rates limit the extent to which precipitates can form, limiting the possible strength without post-thermal treatments).

- Titanium alloys (high gas solubility of titanium requires exceptional shielding; this can be expensive for large powder bed systems requiring very large volumes of shielding gas).

- Gold, silver, platinum, palladium (expensive to fill powder bed with precious metals so special systems are needed).

Design:

Component design is limited by the following:

- Samples need to be removed from the substrate as the substrate is an integral part of the system. This also makes SLM unsuitable for adding structures onto existing components and for repair applications.

- Surface finish is limited by the minimum track size for the set-up – the smaller the track size, the finer the surface finish. SLM has the finest possible track size of any metal-based additive manufacturing system.

- Limited degrees of freedom, limiting design to geometries that can be sectioned into planar layers with no tilts or rotations.

- Powder becomes trapped in internal structures. Method of powder removal needs to be incorporated into design (i.e. no closed cavities).

See Also: Direct metal deposition (DMD), Fused deposition modelling (FDM), 3D printing.

This article is a part of Manupedia, a collection of information about some of the processes used to convert materials into useful objects.

Rate and Review

Rate this article

Review this article

Log into OpenLearn to leave reviews and join in the conversation.

Article reviews