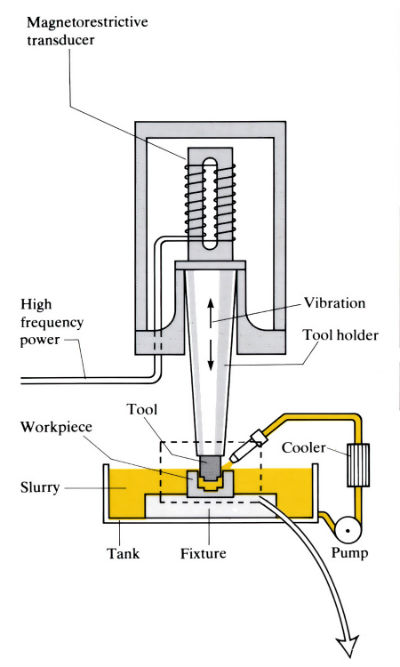

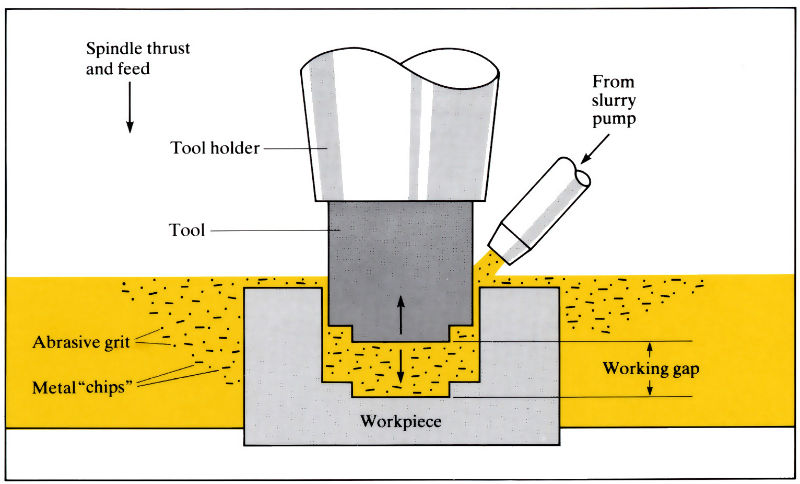

A metal tool is given a high frequency, low amplitude oscillation perpendicular to the workpiece, which transmits a high velocity to fine abrasive particles present between the tool and workpiece. These particles strike the workpiece, chipping away small particles, and the tool is gradually fed into the workpiece. The “chips” are carried away from the workpiece by a constant flow of cooled slurry. The workpiece is abraded into a mirror image of the tool.

In rotary ultrasonic machining (RUSM), the tool is rotated as well as being vibrated. Most commonly used for drilling using diamond-plated drills, giving greater accuracy and cutting speed.

Manufacture:

- An alternative to electrical discharge machining (EDM) and electrochemical machining (ECM).

- Operates in the ranges 200–4000 W and 10–40 kHz. Most common frequency is 20 kHz (beyond audible range), which can be “tuned” to ±10% to give optimum conditions for specific tool/workpiece combinations.

- Metal removal rate is approximately 1 cm3 min-1. (Conventional 3000: ECM 15: EDM 5.)

- Feed rate is sensitive to debris accumulation in the gap, depth of cut, sharpness of grit, etc., but is usually 0.05–2.5 mm min-1.

- Amplitude varies from 5 to 150 µm, but should match the grit size.

- Cutting gap and “overcut” are approximately twice the grit size.

- Abrasive depends on work material, the most common being boron carbide. Grit size depends on cutting speed and surface finish but is usually in the range 100 µm (roughing) to 5 µm (finishing).

- Abrasive concentration is in the range 20–60% (low for large tools), usually in water (although oil is sometimes used for finishing). The slurry is kept at 2–5˚C using a cooler.

- Common tool materials are mild steel, monel, 521100 steel and molybdenum, and are chosen for their toughness and ductility, rather than their hardness. Surface damage should be avoided as it leads to premature fatigue failure.

- Tools are brazed, soldered or mechanically fastened to the tool holder, and the tool tip force is 0.45–45 kg (usually 4.5 kg).

- Tool wear ratios (workpiece erosion/tool erosion) vary from 1/1 (tungsten carbide/tungsten carbide) to 1000/1 (glass/tungsten carbide).

Materials:

- Any material but most effective on materials >40 HVA hardness. Mainly used for glasses and ceramics, but also used on brass and steel where there is no suitable alternative.

- Leaves a shallow residual compressive stress, which can improve fatigue life.

Design:

- Holes ranging from 0.075 to 90 mm in diameter to a maximum depth of 65 mm with aspect ratios of 2.5/1.

- Holes have a taper of up to 0.005 mm mm-1 and can be threaded using a rotating tool.

- Typical accuracy is ±0.025 mm, but ±0.005 mm is possible.

- Surface roughness depends on grit size, frequency, amplitude, etc., but is typically in the range 0.5–1 µm Ra. The sidewalls of deep cavities are often rougher than the face.

- “Breakout” and chipping of exit cuts may necessitate the use of “sacrifice plates” under the workpiece.

See Also: Single point cutting, Multipoint cutting, Electrical discharge machining (EDM) and Electrochemical machining (ECM).

This article is a part of Manupedia, a collection of information about some of the processes used to convert materials into useful objects.

Rate and Review

Rate this article

Review this article

Log into OpenLearn to leave reviews and join in the conversation.

Article reviews