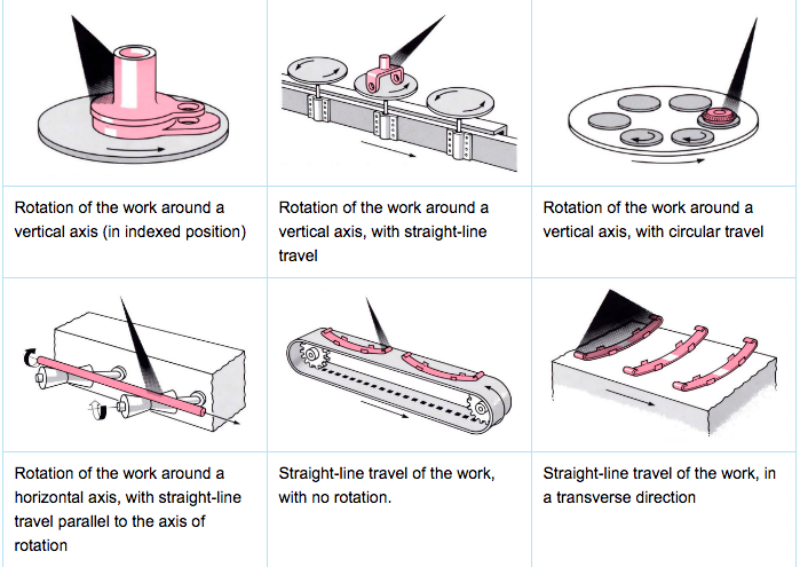

Examples of motion and fixturing used in work-handling equipment for shot peening

Manufacture:

- The equipment used in shot peening is essentially the same as that used in shot blasting, except for certain auxiliary equipment made necessary by the more stringent controls imposed in shot peening.

- The essential elements of a shot peening equipment are a shot-propelling device, a shot-recycling arrangement and a work-handling conveyor.

- The methods of propelling shot are the same as those used in shot blasting: bladed wheel and air nozzle. The wheel method has easier control of shot velocity and freedom from moisture problems encountered with compressed-air lines. The air blast method can develop higher intensities with small shot size, and permits peening of deep holes and cavities.

- Recycling machines control the size of the shot, which is more important in shot peening than in shot blasting applications. Spent shot and fines are removed by air classification.

- To control the evenness of shot intensity, it is essential that all critical areas of a part be evenly exposed to the blast stream. Six different work-handling devices are shown on the front of the card, which incorporate several different motions for a variety of shapes.

- Process controls are very important to control the peening intensity and include:

- size of shot

- velocity of shot

- hardness of shot

- surface coverage

- angle of impingement

- shot breakdown

Materials:

- The main application of shot peening is to improve the fatigue strength of metals and alloys.

- Aluminium alloys are shot peened with cast steel shot (500–750 µm) to increase fatigue strength by 35%.

- Low and medium carbon steels, and low alloy steel, are peened with either chilled cast iron or cast steel shot (500–1250 µm) and fatigue strengths can be increased by up to 50%. Spring steels are widely shot peened for coil- and leaf-spring applications.

- The second major reason for shot peening is to improve the stress corrosion resistance of several alloys, including:

- aluminium alloys (Al-Cu and Al-Zn)

- magnesium alloys (AZ31 and AZ61)

- brass (Cu-Zn)

- stainless steel

- The adhesion of silver-plated bearing surfaces is tested by shot peening. Poorly bonded surfaces blister under this treatment.

- Stainless steel, inconel, manganese steel and stellites can be work hardened by shot peening.

- Titanium and magnesium alloys have also been peened successfully.

Design:

- There are few practical limitations in terms of size, shape, quantity, surface condition or surface hardness.

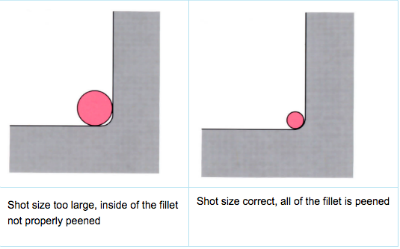

- The peening of small radii in fillets and thread roots is limited by the smallest available shot size, and sharp edges that have to be retained should be stopped-off.

- Water, oil or grease left on surfaces will contaminate the shot.

- Aluminium parts should be peened before anodising.

- All sizes and many types of shafts and axles are peened to improve their fatigue strengths. In some instances peening is required only in keyways, splines or fillets (the rest is stopped-off).

- Gears are usually peened in the fillets of the root of the gear form and after carbonitriding.

- Connecting rods are usually peened all over, except for the bores, to increase fatigue lives by 75–100%.

- Cylinders are often peened before hard chrome-plating.

See also: Shot blasting, Induction/flame hardening, Carbonitriding/caburising and Plasma nitriding/carburising.

This article is a part of Manupedia, a collection of information about some of the processes used to convert materials into useful objects.

Rate and Review

Rate this article

Review this article

Log into OpenLearn to leave reviews and join in the conversation.

Article reviews