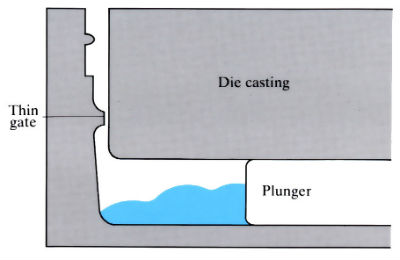

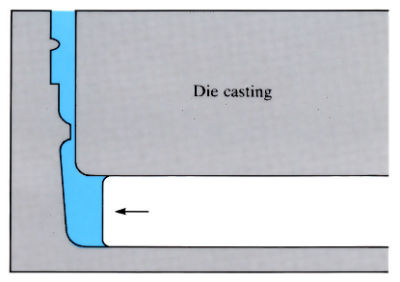

High pressure die casting

High pressure die casting uses a single plunger and a narrow in-gate, which causes turbulence and high levels of porosity.

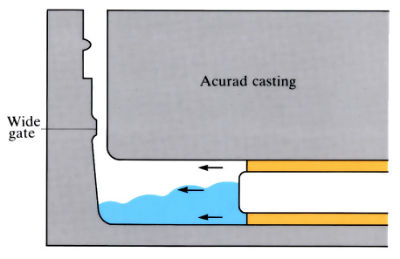

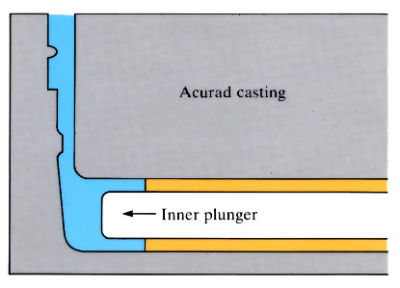

The Acurad process (die casting with secondary plunger)

In the Acurad process, the high pressure die casting process is modified. A secondary plunger is used a fraction of a second after the initial plunger has operated, in order to feed the shrinkage porosity. A larger in-gate is designed into the die to reduce turbulence during injection.

Manufacture:

- Acurad process uses a modified high pressure die casting machine, as follows.

a. The gate is made as large as possible to prevent turbulence and air entrapment; it is positioned at the lowest point in the die cavity to allow for gravity defects.

b. A secondary plunger delivers a delayed action (time delay 0.015–1.5 s, depending on size of casting) pulse of pressure to feed shrinkage.

c. Dies are water-cooled to optimise directional solidification with automatic die temperature control. - Total Acurad cycle time is about the same for conventional die casting. The increased fill time is offset by the reduced solidification time.

- Lower pressures are used for Acurad than with die casting:

Acurad 35–100 MPa

die casting 70–140 MPa - Reduced operating pressures and speeds improve machine downtime and die lives.

- Reduced impact shock pressure reduces the frequency of hydraulic equipment breakdowns.

- There is also less thermal shock to the dies, heat checking of the dies is reduced and erosion at the in-gate is reduced.

- Range of components includes car wheel trims, transmission casings, engine blocks, and motorcycle and bicycle components.

Materials:

- Mainly used for aluminium die casting alloys. Magnesium- and zinc-based also can be used.

- Difficult-to-cast aluminium alloys can also be used for some components.

- Improvements in tensile strength by up to 30% are claimed. Tensile ductility can be improved from values of 1–3% (for die casting) up to 10% (for Acurad castings), e.g. Al-(6.5-7.3)Si-(0.2-0.45)Mg alloy in T6 heat treated condition, seen below.

- Reduced porosity and air entrapment enables aluminium alloys that would not normally be treated after die casting to be welded and/or heat treated.

- Castings are pressure-tight.

| Die cast | Acurad | |

|

Tensile strength (MPa) |

230 |

280 |

|

0.2% proof strength (MPa) |

200 |

235 |

| Elongation (%) | 2 |

10 |

Design:

- Acurad process enables designers to design for higher allowable stresses.

- Wall section thicknesses can be reduced compared with die casting, with a consequent decrease in the volume of metal required per casting.

- Acurad castings can be used for pressure-tight, weldable and heat treatment applications.

- Castings have smooth surfaces.

- Intricate design details can be cast.

See Also: Hyperforge process, Squeeze forming, Pore-free die casting and High pressure die casting.

This article is a part of Manupedia, a collection of information about some of the processes used to convert materials into useful objects.

Rate and Review

Rate this article

Review this article

Log into OpenLearn to leave reviews and join in the conversation.

Article reviews