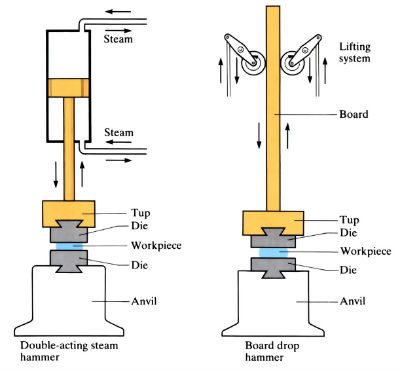

Two types of hammer used for open die forging:

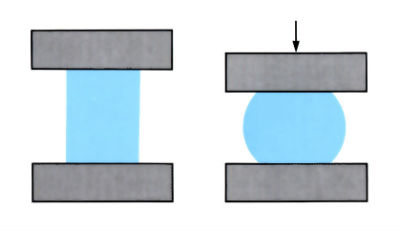

Open die forging between flat dies:

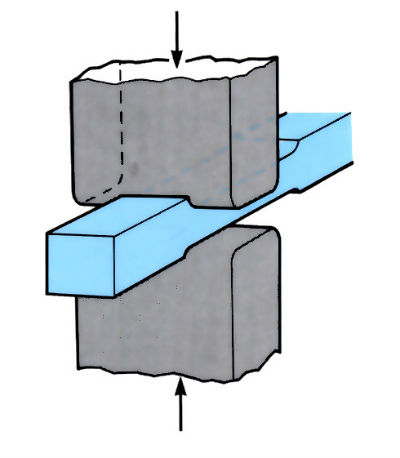

Open die forging between flat narrow dies:

Manufacture:

- There are a wide variety of open die hot forging processes; including slab, shaft, mandrel, ring and hollow forging.

- Forgings vary in size, ranging from 0.5 kg up to 300 tonne shaft forgings.

- Mainly performed on gravity drop, double-acting and counterblow hammers. A forging hammer is a mechanical version of the blacksmith’s hammer and anvil. It consists of a heavy mass or tup, which is allowed to fall or is driven down onto the workpiece, and an anvil on which the hot workpiece is placed. They are very versatile and relatively quick in action. Deformation is achieved by a rapid succession of hammer blows. Energy rating of hammers range from 500 to 40,000 kg-m.

- Hydraulic presses are used for large forgings such as large turbine shafts. They are slow in operation and the workpiece often requires to be reheated several times.

- In most cases shaping of the component relies on the skill of the forgemaster. Larger workpieces are supported by chain slings or semi-automatic manipulators.

Materials:

- A wide range of metals and alloys are forgeable at temperatures > 0.6Tm (where Tm is the melting point).

- Plain carbon steels (0.30—0.50 wt% C) and low alloy steels containing 1% Cr, 1.5—4.0% Ni, 0.30—0.50% Mo and 0.60% Mn are all readily hot forged in open dies (this includes carburising steels).

- The majority of aluminium alloys are hot forged with little problem; including the aluminium/magnesium/silicon series (6000) and the aluminium/copper-based alloys (2000).

- Titanium alloy ingots are initially hot worked before further deformation. This includes the Ti-6Al-4V alloy, which has excellent forgeability. Initial ingot breakdown is done just above the β transus temperature. Any further forging is done between the α and β transus temperatures.

Design:

- A wide range of sizes, shapes and properties are available to the designer.

- Open die forging design is dependent on the size and type of metal being forged.

- Machining allowances are large to enable any surface defects to be removed. For aluminium allowance is 1.5 mm, steels 3 mm and titanium 6 mm.

- Design factors:

| Aluminium alloys | Steels | Titanium alloys | |

|

Minimum flange thickness (mm) |

5 | 5 | 6.3 |

|

Minimum web thickness (mm) |

5 | 9 | 15 |

|

Minimum radius (mm) |

6 | 12 | 12 |

|

Die wear factor (per 25 mm of dimension) |

x 0.004 |

x 0.005 |

x 0.009 |

| Draft angles (degrees) | 3 | 5—7 | 5—10 |

5. Tolerances vary depending on the size of forging:

up to 50 mm diameter + 0.80 mm

50—200 mm diameter + 1.60 mm

See Also: Hot forging (closed die), Upset forging, Orbital forging, Axiforge process, Cold forging and Warm forging.

This article is a part of Manupedia, a collection of information about some of the processes used to convert materials into useful objects.

Rate and Review

Rate this article

Review this article

Log into OpenLearn to leave reviews and join in the conversation.

Article reviews