5.3 The systems engineering methodology used in the course

The aim of systems engineering is to achieve a solution that is effective and sustainable through its life cycle, together with the associated processes and facilities needed to realise the system and introduce it into the real world. Therefore it is important that systems engineering is itself conducted in full consideration of the following five systems:

-

the technology development system that provides new or modified technology for the other systems

-

the product or service system – this is the primary output of the transformation process

-

the realisation system – the resources needed to produce or effect the product or service system

-

the sales and marketing system – most changes to systems have to be sold in some way or another to purchasers or users

-

the support system – most systems have a life of several years, during which time they need to be supported and maintained. The forms that these requirements may take are technical support, spares and maintenance, training, logistics, and the possibly important issues surrounding disposal after use.

Any one or, more rarely, more than one of these systems can be the system of interest – that is, the system that is at the focus of the systems engineering effort. For example, the development of an aircraft would imply a new or enhanced product system. In a systems engineering project to design and implement a new production plant the realisation system would be the primary focus.

A change to any one of the five systems will almost invariably result in changes to the others – the secondary systems. Assessing the degree of potential change in the overall system of systems is an important activity that takes place during the tendering or feasibility process.

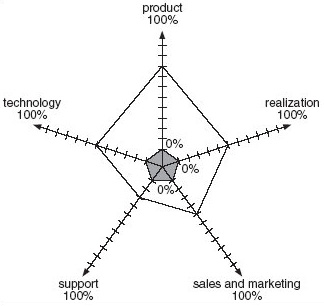

Core techniques for assessing the degree of change in the system of systems are illustrated by the systems engineering difference assessment web (SEDAW). This is a single representation on a polar graph of the amount of change involved in each of the system of systems. For example, a major new model programme in the car industry involved changes in the other four systems. The Programme Development Team assessed the degree of change by carefully evaluating how much each system would have to be changed to accommodate the new model. The degree of difference in each system is shown in Figure 51.

It is important when making such an assessment to distinguish between doing a different thing and doing something differently. For example, at one extreme the fashion industry changes its product lines regularly but with hardly a difference to its systems. The other end of the scale would be represented by a new airliner requiring significant new technologies to be incorporated into the product and the production systems.

Any system will have what is termed a life cycle, and ISO/IEC 15288 defines the stages in this as:

-

concept

-

development

-

production

-

utilisation

-

support

-

retirement.

Associated with these stages are the set of technical processes:

-

stakeholder requirements definition

-

requirements analysis

-

architectural design

-

implementation

-

integration

-

verification

-

transition

-

validation

-

operation

-

maintenance

-

disposal.