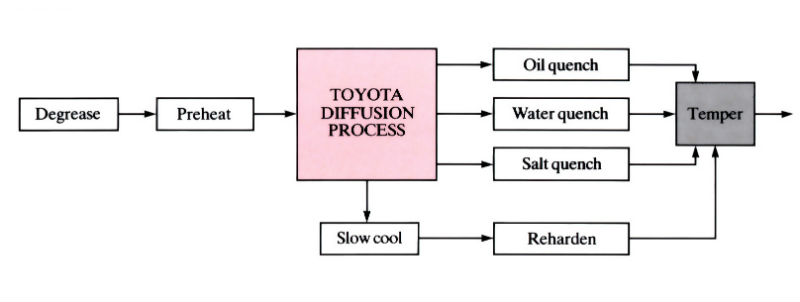

TD flow diagram

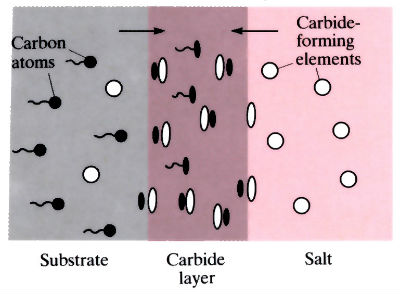

Mechanism of carbide layer formation

TD process is based on salt bath heat treatment. Carbide layer is formed by migration of carbon atoms from the substrate to the surface, where they combine with carbide-forming elements (V, Nb, Cr) in the molten salt bath, to produce a wear resistant carbide layer (3000–3600 Hᵥ).

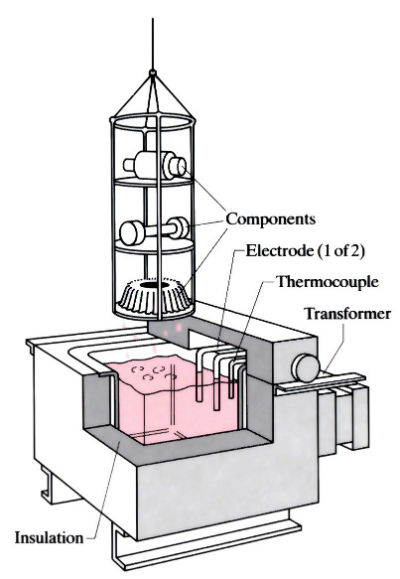

Salt bath

Manufacture:

- Toyota diffusion (TD) process is carried out in a salt bath of borax and mixed alloy carbides at 1050°C.

- Tools and dies may be directly hardened from the salt bath.

- The carbides used are vanadium, niobium and chromium carbide. Vanadium carbide is preferred.

- The coating layer is pore-free and is formed by diffusion of the carbon atoms diffusing from the steel matrix.

- The thickness of the layer is controlled by the process time, bath temperature and composition of the base material.

- Process times range from 30 min up to 10 h to obtain optimum thicknesses in the range 5–15 µm.

- No expensive vacuum chambers are required such as those used for PVD processes, and no gas-tight reaction vessels are required such as those used for CVD processes. No unpleasant by-product gases, as produced by CVD processes.

Materials:

- TD process has mainly been used on tool steels to increase their lives in applications such as hot and cold forging, powder compaction, die casting, and rubber and plastic moulding.

- Tool steels include the following: H13 hot working tool steel (Fe–5Cr) D2 ASP30, produced by hot isostatic compaction.

- The coating grows by reaction of the carbide-former and carbon atoms diffusing from the matrix.

- The hardness of the vanadium carbide layer is in excess of 3000 VPN, which is higher than most other similar processes.

- Very hard carbide layers provide excellent wear resistance to steel and, in some instances, are better than those treated by nitriding, chromium plating and thermal spraying.

- Coatings have excellent abrasion resistance when in contact with non-metallics such as sand and glass.

- Coatings have high seizure and scoring resistance.

- Impact and fatigue resistance are not affected by the process.

- If corrosion or oxidation resistance of the coating is of prime importance, then chromium carbides are preferred.

- Thermal shock resistance of hot work steels is improved.

- Cratering of carbide cutting tools is reduced.

Design:

- Surface finish is maintained in the TD process unless the original surface finish is better than 0.5 µm Ra, saving on labour on die polishing.

- No further finishing is needed if the surface is polished to the required level before treatment.

- If a finish better than 0.5 µm Ra is required, then diamond lapping must be applied.

- Growth is equal to the carbide layer thickness.

- Tool lives have been improved in a wide range of applications. See the table below.

- There are cost savings on die materials, lubricants, die polishing and product finishing.

- There are improvements in product quality due to better surface finish and dimensional accuracy.

| Type of tooling |

Life increase factor |

Life increase / cost increase |

|

Piercing punch (cold work steel) |

5–10 |

2–8 |

|

Cold forging punch (HSS) |

5–10 |

2.6–5.2 |

|

Carbide cold forging punch replaced by HSS with VC coating |

1 |

5.6 |

|

Core pin for aluminium gravity diecasting using H series die |

3–5 |

2.3–3.8 |

|

Hot forging dies |

2–5 |

— |

|

Extrusion dies |

2–15 |

— |

|

Steel powder compaction |

10–30 |

— |

|

Plastic moulding |

5–10 |

— |

| Aluminium diecasting | 2–10 |

— |

See Also: Chemical vapour deposition (CVD), Physical vapour deposition (PVD), Electroless plating and Electroplating.

This article is a part of Manupedia, a collection of information about some of the processes used to convert materials into useful objects.

Rate and Review

Rate this article

Review this article

Log into OpenLearn to leave reviews and join in the conversation.

Article reviews