4.2.3 Monitoring MOC in cleanrooms

In addition to microbial contamination, planetary protection guidelines require clean assembly protocols to minimise particulates, dust and molecular organic compounds.

-

Can you suggest another reason why minimising MOC might be important?

-

MOC can also cause the degradation of spacecraft surfaces or even prevent adequate bonding between materials.

The organic substances that could contaminate hardware and vacuum chambers used in the process of building and cleaning hardware can include:

- Volatile condensable materials outgassing under vacuum

- Volatile condensable materials off gassing directly

- Back-streaming of materials from pumping systems

- Residues from cleaning agents

- Handling residues (e.g., human fingerprints)

- Creep of substances (e.g., silicones)

- Non-filtered external pollution.

Two methods are employed to detect and measure MOC in cleanrooms: direct and indirect.

Direct methods use infrared (IR)-transparent ‘windows’ to capture organic compounds on their surfaces and are positioned at critical locations around the cleanroom. We call these windows witness plates as they act as a proxy for any other surface that MOC could accumulate onto and they are made of materials such as zinc selenide, germanium, or calcium fluoride. The plates are then analysed using IR-spectroscopy that can determine the presence and identity of any groups of organic compounds (hydrocarbons, esters, and silicones are the most concern).

IR spectroscopy is a common analytical technique that detects the absorption of light by a compound in the IR region of the electromagnetic spectrum. Different chemical bonds will absorb IR radiation at different areas of the IR spectrum, referred to as wavenumbers. An IR spectrometer is a relatively simple device consisting of a lamp or heated rod that will emit light in the IR region. A detector then collects all wavelengths of IR radiation that have passed through the sample and converts these to wavenumbers. Each type of molecule will have a different pattern of wavenumbers, so identification can be made.

Indirect methods involve rinsing a surface with a solvent, which is then evaporated until a few drops remain and this liquid is transferred to an IR-transparent window. Further evaporation occurs of the remaining solvent, and the window is analysed by IR-spectroscopy. A second indirect method uses pre-cleaned tissues to wipe a surface (wet or dry) eight times. The tissue is then immersed in solvent, removed, and the solvent analysed by IR-spectroscopy.

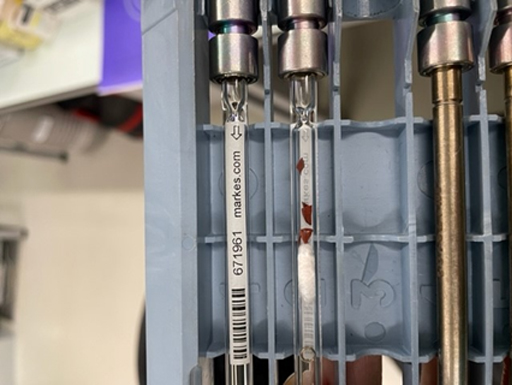

New methods of sampling and determining organic contamination within cleanrooms are also in development (Figure 31), that can give near real-time results by identifying and detecting organic molecules that are emitted by materials within a cleanroom, such as adhesives, lubricants and the flight hardware itself. By identifying these volatile organic compounds (VOCs) individually, unlike the IR-spectroscopy that identifies groups of compounds, steps can then be taken to mitigate the contamination more efficiently and effectively, since many VOCs will behave very differently under the same conditions. This technique can also be used to help identify organic compounds from returned samples in a way that is non-invasive, thus not further contaminating any precious samples.