Strategy 3: Improving technology

Burning or incinerating MSW dramatically reduces the volume of waste to be dealt with and is an important way of dealing with the waste problem in China. However, a modern plant should not be designed just with mass reduction in mind.

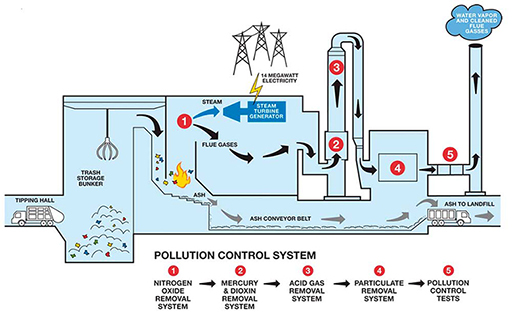

The technology has been developed worldwide to use the heat energy generated in an incinerator either to heat water that can be piped to homes and businesses or to generate electricity, such as is shown in Figure 10. Such incinerators are more properly called waste-to-energy (WtE) or energy-from-waste (EfW) plants. The outputs of burning, such as ash and gases, should be treated to render them as harmless as possible before they are emitted to the environment. For example, combustion conditions can be very tightly controlled to destroy harmful chemicals. Countries such as the UK, and in much of Continental Europe where EfW plants are widely used, operate under strict legal regulations concerning what they can emit to the atmosphere.

The need for pre-treatment of materials from the MSW stream can be further reinforced if energy from waste is a chosen treatment option. EfW plants are not incompatible with recycling, since materials can be taken out for recycling before burning (e.g. food waste), or before and after combustion (e.g. metals).

While landfill should be the last resort for the disposal of waste, it is widely used in China and there will always be types of waste – for example, the ashes from incineration, or materials that cannot be recycled – that will end up being landfilled.

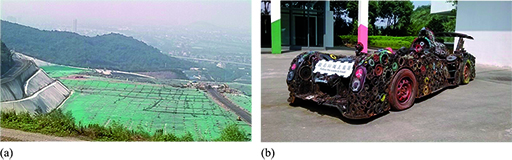

The engineering of modern, well-run landfill sites is designed to prevent uncontrolled emissions of leachate and gas from the decomposition of waste, to the environment. This is mainly achieved through the use of an impermeable butyl or clay liner and engineering the collection of leachate which is treated. Landfills should be operated so that vermin are controlled by covering the waste every day and capping with an impermeable material when no longer in use. An example of how this can be done has been undertaken in Hangzhou. Hangzhou is a tourist destination celebrated for its beautiful mountains and old architecture, which now adds the Hangzhou Ecopark to its list of attractions. The local landfill site incorporates China’s first industrial landfill gas power plant, where gas from the anaerobic decomposition of waste is collected through a network of pipes and burned to generate electricity (Liu, 2011). This is part of the visitor attractions, which include sculpture made from recycled materials, and displays and games to encourage recycling (see Figure 11). The Ecopark is even marketed as a wedding venue.

There are efforts across China to develop more controlled landfill sites. Returning to Lugu Lake discussed in Box 1, Tian Song’s story has developed since the year 2000.

Box 4 A case study: garbage of Lugu Lake, Yunnan province (continued)

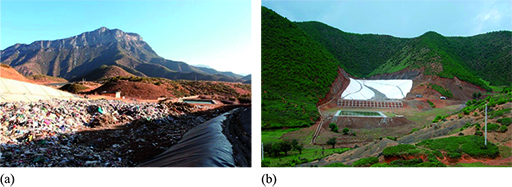

Much has changed at Lugu Lake as a new managed waste site nearby (Figure 12), which is now taking the waste on a regular basis, was established in 2006 about 30 km away. The land it was built on was previously owned by the county government and the system can be considered a formal one.

However, Tian notes:

The dump was designed for a 20 year lifespan – meaning it can hold the capacity of that much municipal waste before it is full – when we consider that 2026 is not very far away in time it is rather worrying. The site takes rubbish from the hotel which runs nearby and local workers charge to burn some rubbish and compact the rest.

Activity 4 Thinking about your own waste habits at home

- a.How do you separate your waste for collection?

- b.Do you know how the separated waste is treated and where it goes?

- c.How does this fit with the waste hierarchy? Could you do more to reduce your waste?

Discussion

An example answer:

- a.In my household there are five of us, all either working full-time or going to school full-time. Our city council uses three types of bin: a green composting one which can take all forms of food and garden waste, including bones and meat, and can also take a limited amount of cardboard and paper which does help reduce the fluid that accumulates in the bottom. There is also a blue recycling bin which takes mixed recycling including glass, metals, plastics, Tetra-Pak style cartons, styrofoam, paper and card/cardboard. The black bin is for all other items. The city operates a weekly collection, with odd weeks being ‘black’ only and even weeks being green and blue collections. The blue bin also has the capacity to accept batteries for recycling – these get looped over the handle in a specific clear bag provided by the operator.

- b.I looked on my local city council’s website which was very informative about where my waste goes. When the blue bin lorries are full, they take the recycling to the ‘Materials Recycling Facility’ (MRF) where items are separated further and sold to recycling plants. The contents of the green bins are taken to the ‘in-vessel’ composting plant; the resulting soil conditioner is sold for local agriculture and is available for anyone to buy for the garden. The contents of the black bins are taken to a Mechanical Biological Treatment plant (MBT). The MBT mechanically removes some items from the waste and then treats the rest in a huge treatment hall. This breaks down the waste as much as possible, helping to reduce methane and carbon dioxide emissions, before it is landfilled. I also noticed that the MRF, the MBT plant and the in-vessel composter are all owned and operated by the same privately-run company.

- c.I can see that my waste is being recycled via the blue bin system, and there is recovery from waste via the composting system for green and food waste, but the material recovered seems to be of low value. All this fits in with the waste hierarchy. In general, I think our overall waste is indeed reducing over time – but I also noticed an interesting thing about our green bin. With respect to garden waste, I used to compost my own in a small wooden box in the back yard but now with the green bin being so close by I tend to sweep up everything and put it in there. In other words, my waste habits have changed due to the introduction of different management systems.