4.2 Metallic materials

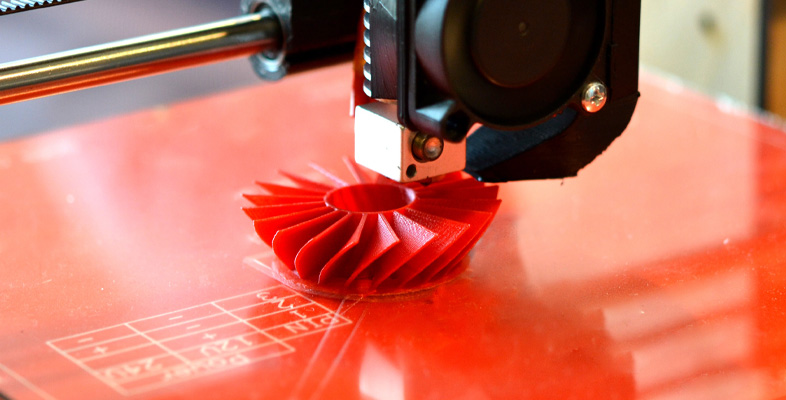

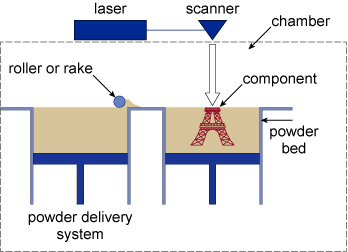

Powder-bed systems are designed to be used with metallic materials. Figure 19 shows a powder-bed system. Powder is added to the workpiece in a thin layer using a roller or rake. The layer is then consolidated. A metal is usually fully melted but sometimes it is only sintered (compacted and heated). Lasers are the most common choice for an energy source because of the powers and wavelengths available, but electron beams have also been used. Electron beams require a high vacuum though and are therefore less popular.

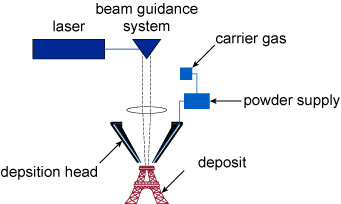

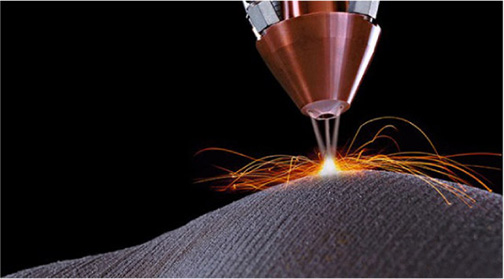

The powder-feed system shown in Figures 20 and 21 delivers material through a powder nozzle directing a stream of powder into the path of a laser or electron beam. A wire can be used instead of the powder stream.

Both powder-bed and powder-feed systems have benefits and drawbacks (Table 1).

| System | Benefits | Drawback | Potential applications |

| Powder bed | No powder is lost Precise layer thickness | Constrained to the three-axis system | Semibulk production Production line integration |

| Powder feed | Freedom to change z direction System can be taken to existing components – deposition in situ | Powder usage efficiency is low As component grows, variations in layer height may occur | Repair of damaged components Addition of detail to large structures |