Manufacture:

- Process is not a surface coating process but implants ions below the surface, into the matrix of the original material, in a similar manner to diffusion processes but at a much lower temperature (200°C).

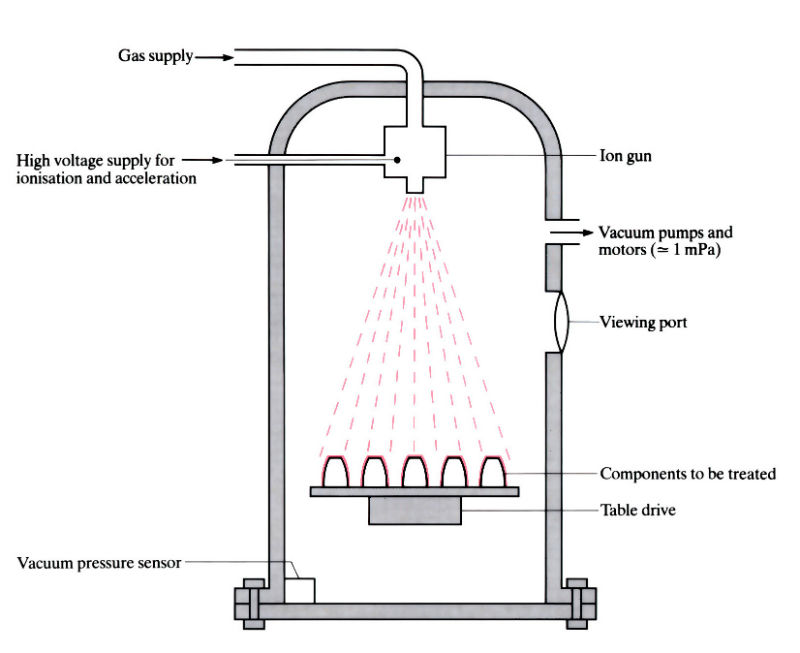

- Unlike ion plating and ion nitriding, which have a good “throwing power”, ion implantation is a “line of sight” process (cf. CVD).

- Ion energies are high (50–200 keV) compared with ion plating (0.1 keV).

- Ion dosage varies with ion species, component material and property requirements, but is typically in the range 1015–1018 ions cm-2.

- Implantation times depend on component material, surface area and property requirements, but are typically in the range 2–10h.

- Process is more reproducible than many of the conventional surface treatments and can be continuously monitored by measurement of the ion beam current.

- Components require no further treatment before use (unlike CVD).

- Process is more costly than conventional and well-established surface hardening treatments, but as more equipment becomes available and as industry realises the full potential of the process, the cost will become increasingly competitive.

- Process finds its major use in tooling for cutting, pressing, punching, extrusion, moulding and stamping. Typical applications, materials and results are shown below.

|

Application |

Material |

Result |

|

Paper slitters |

1.6%Cr-1%C steel |

Cutting life x 2 |

|

Punches for acetate sheet |

Cr-plated steel |

Improved product |

|

Taps for phenolic resin |

M2 high speed steel |

Life increase up to x12 |

|

Thread-cutting dies |

M2 high-speed steel |

Life increase x5 |

|

Slitters for synthetic rubber |

Co-cemented WC |

Life increase x12 |

| Tools inserts |

4%Ni-1%Cr steel |

Contamination reduced |

| Forming tools |

Carburised mild steel |

Greatly reduced wear |

| Dies for copper rod |

Co-cemented WC |

Throughput x5 |

|

Deep-drawing dies |

Co-Cemented WC |

Improved life |

| Dies for steel wire |

Co-cemented WC |

Life increase x3 |

| Injection moulding nozzle |

Tool steel |

Much reduced wear |

| Swaging dies for steel | Co-cemented WC | Life increase x2 |

Materials:

- Although all elements can be ion implanted, the process is usually restricted commercially to nitrogen and carbon ions. However, the process has the capability to implant ions which would not normally diffuse or are insoluble in the matrix material.

- Most ions are implanted for improved wear and oxidation and fatigue resistance, although resistance to aqueous corrosion has been shown to be dramatically improved by the implantation of noble metals.

- Nitrogen implantation is unsuitable for components which reach high temperatures, such as HSS twist drills, since at these temperatures (>800°C) the mobility of nitrogen atoms is so great that they rapidly diffuse away from the surface.

- Compressive stresses are set up in the surface, which improve fatigue and wear resistance. Nitrogen implantation of steel and titanium has been shown to improve fatigue resistance by a factor of 10 and the wear resistance of steel has been drastically improved by nitrogen implantation.

- Ion implantation can be carried out on virtually all ferrous and non-ferrous materials, but it is presently used mainly for steels and cemented carbides. The process can be readily applied to components which already have a surface coating, such as chromium plating.

- Material costs are low due to the small amounts used, thus enabling expensive materials, such as noble metals and rare earths, to be implanted.

Design:

- Distribution of implanted ions shows a Gaussian distribution with the maximum concentration at 0.1 to 0.3 μm depth.

- There is no definable interface which could be subject to mechanical weakness or interfacial corrosion, and the maximum ion concentration is often in the region of the peak Hertzian stress.

- Under adhesive wear conditions frequently encountered in tools, the heat generated at asperities causes the nitrogen to diffuse into the component, thus effectively increasing the depth of hardness during use.

- Component size and weight depend on equipment available, but ion implantation units are currently in use with chambers 2.5 m long and 2.5 m in diameter, and work-tables capable of carrying 1000 kg.

- Components with a small volume/surface ratio have a low thermal capacity and may have to be manipulated within the chamber to prevent an excessive temperature rise.

- No appreciable change in dimensions occurs and the process can thus be used in the final stage of production.

- The ion bombardment produces a slight polishing of the surface and surface finish is often improved.

- Complex shapes are difficult to coat evenly since it is a “line of sight” process, but this can be partially overcome by rotating the work-table. The use of multiple ion sources will probably eliminate this problem in the near future.

See Also: Chemical vapour deposition, Physical vapour deposition, Carbonitriding/carburising, Induction/flame hardening, Plasma nitriding/carburising, Electroless plating, Electroplating.

This article is a part of Manupedia, a collection of information about some of the processes used to convert materials into useful objects.

Rate and Review

Rate this article

Review this article

Log into OpenLearn to leave reviews and join in the conversation.

Article reviews