1.4 Results of finite element analyses

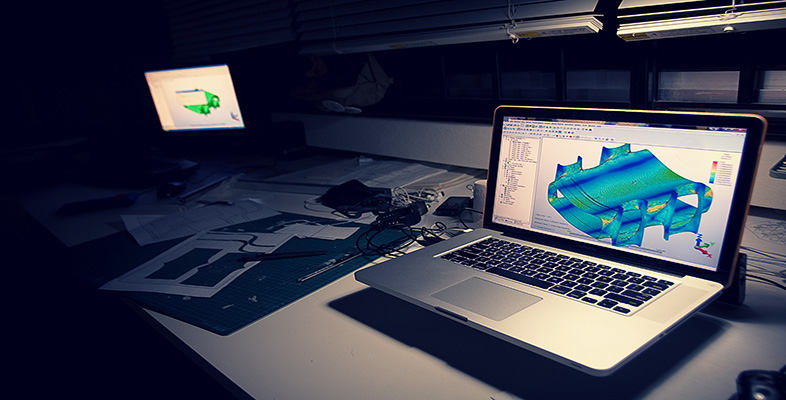

The amount of information that can be produced by an FEA system, especially for non-linear analysis, is enormous, and, for the first-time user, can be daunting. For the main areas we are considering, most general-purpose finite element codes provide the capability to determine the items in Box 2, again adapted from Baguley and Hose (1994). Results can be presented in various forms such as tabulated numerical data, line graphs, charts and multicoloured contour plots.

Box 2 Results from finite element analysis

7. Typical information generated by a stress analysis

- deflections

- reactions at supports

- stress components

- principal stresses

- equivalent stresses (Tresca, von Mises, etc.)

- strains

- strain energies

- path integrals and stress intensity for fracture mechanics

- linearised stresses

- buckling loads

- buckling mode shapes.

8. Typical information generated by a dynamic analysis

- natural frequencies

- natural mode shapes

- phase angles

- participation factors

- dynamic analysis

- responses to loading

- displacements

- velocities

- accelerations

- reactions

- stresses

- strains.

9. Typical information generated by a thermal stress analysis

- temperatures

- heat fluxes.

10. General information generated by a thermal stress analysis

- displaced shape plots

- symbols showing the magnitude of reaction forces, heat fluxes, etc.

- contour plots of stresses, strains, displacements, temperatures, etc.

- vector plots showing the direction and magnitude of principal stresses, etc.

It cannot be emphasised strongly enough that while most FEA systems produce vast amounts of data and pretty, highly persuasive pictures, it is the user’s responsibility to ensure correctness and accuracy. They are, in the end, approximate models and solutions, albeit highly sophisticated ones, and it is the user’s responsibility to ensure that results are valid. In the absence of such awareness, the system degenerates into a ‘black box’ category, and the solution it provides will almost certainly be wrong, despite the impressive-looking results.

To summarise: modelling is an important part of modern engineering. FEA is a powerful tool for evaluating a design and for making comparisons between various alternatives. It is not the universal panacea that replaces testing, nor should it allow users to design products without a thorough understanding of the engineering and physical principles involved.

The qualification of assumptions is the key to successful use of FEA in any product design. To achieve this, it is essential to:

- appreciate the physics and engineering inherent in the problem

- understand the mechanics of the materials being modelled

- be aware of the failure modes that the products might encounter

- consider the manufacturing and operating environment of the product and how these might impinge on the performance

- assume that the FEA results are incorrect until they can be verified

- pay close attention to boundary conditions, loads and material models.

Remember that there is an assumption behind every decision, both implicit and explicit, that is made in finite element modelling.