3.1 Exercise: Analysis of a plate with a hole

Problem description

This is a simple problem with a known solution. It consists of a tensile-loaded thin plate with a central hole. Because of symmetry we need only model a quarter of the plate. The full plate is 1.0 m × 0.4 m with a thickness of 0.01 m. The central hole has a diameter of 0.2 m.

The plate is made of steel with a Young’s modulus of 2.07×10 11 N/m 2 and a Poisson’s ratio of 0.29. The horizontal tensile loading is in the form of pressure of 1.0 Pa (N/m 2 ), along the vertical edge of the full plate.

Interactive time required

60 to 70 minutes

Features demonstrated

Solid modelling, including primitives, Boolean operations, meshing and refinement.

Summary of steps

- Specify title

- Define parameters to be used for geometry input

- Set preferences

- Define element types

- Element options

- Define material properties

- Create rectangular area

- Create circular area

- Subtract hole from plate

- Mesh the area with a default mesh

- Apply displacement constrains

- Apply pressure load

- Solve

- Plot the deformed shape

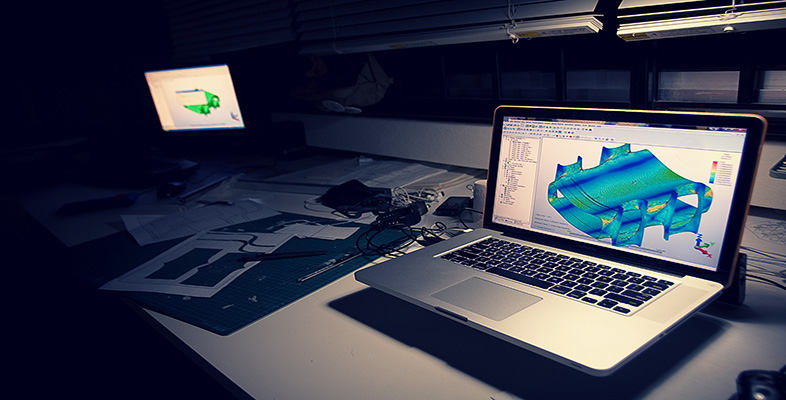

- Plot the element stress in the x-direction

- Refine mesh

- Refine mesh near hole

- Re-introduce the loads

- Read in the new data set and plot the element stress in the x-direction

- Exit the program.