7 Ergonomics and human factors

This section discusses designing for human capabilities and limitations. It introduces the study of ergonomics which can offer general guidelines as well as specific suggestions for good, user-centred product design.

Taking the user as the central point of reference for the design and evaluation of products is the approach encouraged by ergonomists.

The field of ergonomics (also known as human factors engineering) is the systematic study of human capabilities, limitations and requirements, and the application of such knowledge to design. The name comes from the Greek ergos, meaning work, and nomos, laws. So it means, literally, the laws of work. This title reflects the origins of the approach, which lay in attempts to improve the performance efficiency of industrial workers and military personnel, through rational, scientific enquiry into human needs and behaviour.

There are two things, therefore, that distinguish ergonomics both from other professional design approaches and from common sense. Firstly, satisfaction of relevant user requirements is the overriding criterion, and secondly, the approach is based on the application of scientific enquiry to the problem of ascertaining human performance, abilities and limitations.

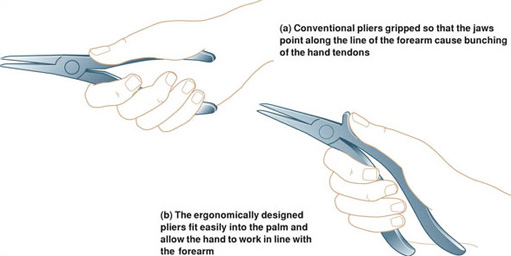

A simple example will illustrate the principles of how ergonomics can be applied in design. Figure 10 shows two designs for pliers.

The pair at the top are a familiar conventional design, which appears to make good economic and practical sense. The tool is made in two identical parts, therefore minimising production costs, joined with a pivot. The overall form has evolved over generations from crude forebears such as blacksmiths’ tools and acquired a certain elegance and wholeness in its appearance. The design looks as if it has reached an end point in the process of evolution towards a perfect form. The pair below, on the other hand, look awkward and are made out of two very different halves. Yet trials have shown this ergonomically designed pair are more comfortable and efficient to use than their classical predecessors. The reason the conventional design is inferior is because to use it you have to bend your wrist in such a way as to cause unnecessary strain. The ergonomic design is based on studies of the anatomy of the hand, wrist and arm, in particular how the muscles and tendons operate, and the study of how people hold and use pliers.