IMTA in Sanggou Bay, China

IMTA in Sanggou Bay, China

The approached to IMTA differs greatly between the western world and China. Variations of IMTA have been practised in China for hundreds of years, so they have long traditions and knowledge. China is one of the world’s most successful countries for commercial-scale

IMTA.

People like diverse plates of seafood, which promotes the sector and creates a market demand for a variety of seafood species. IMTA is recognised by the farmers as of benefit both in sea usage and economic income. And there is a demand

for sustainability because of environmental pollution problems in China and also other places in the world. The government wants ecological aquaculture to allow economic and social development. IMTA is a method to satisfy the social-economic request

and to ease the environmental pressure.

From being introduced by Jianguang Fang since the 1990s, IMTA has been practiced for more than 20 years, and it has turned out to be effective. The current commercial-scale IMTA in China is an accumulation of decades of practical experience adapting to

hydrology, material/nutrient cycle, organism physiology, and the regulation policies locally.

The researchers and farmers initiated the IMTA. There was national funding to promote IMTA technology development over the past decades. The funding helped to improve technology and methodologies. Up to 2019 there was a national regulation as a suggestion

to promote the development of sustainable aquaculture in the whole country, and IMTA was a part of the many suggested practises. The expertise of IMTA in China can be a reference for the EU and others to develop the local version as technical storage

for further sustainable development requests and to deal with global climate change situations.

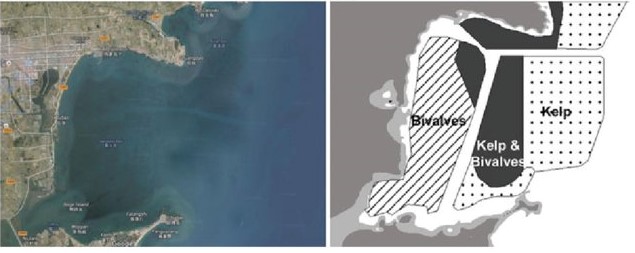

The aquaculture site of YSFRI, used in IMPAQT, is located at Sanggou Bay, Rongcheng city, which is at the east end of the Shandong Peninsula, China. The local aquaculture industry operates the pilot, and among them, Chudao Aquatic Food

Co., Ltd, our collaborator. The area of the bay is 140km2, and nearly two-thirds of it is used for the long-line aquaculture of kelp Saccharina japonica or Pacific oysters Crassostrea gigas. Production of kelp and oysters are 84,500

tons (dry weight) and 60,000 tons (wet weight), respectively. This video gives a good perspective of the size and scale of IMTA production in Sanggou Bay.

The current practice regarding IMTA in Sanggou Bay is the integrated aquaculture of kelp and oysters with the long-line method, as mentioned, and some sea cucumber on the sea bed. The aquaculture of kelp usually starts in November and harvest begins the

following April, until August. For oysters and sea cucumber, they are cultured all year round and harvested depends on the season and market demand.

Commercial IMTA covers more than 60% of the bay area and produces considerable amounts of seaweed, shellfish, sea cucumber, and other species. The IMPAQT pilot site in Sanggou Bay involves multiple aquaculture industries.

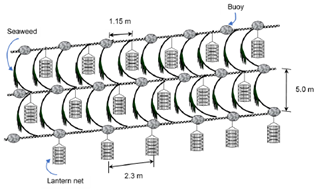

The main method of cultivation in the IMTA site is using longlines, with seaweed and shellfish being the main species. Polyethylene rope is used as the raft rope. The total length of the rope is generally about 150m, with about 100m of which can be used

for cultivation. There are about 25m at each end called a warp attaching to the heavy weight anchor or stake anchor. The gap between the two parallel ropes is 5m for the seaweed and 7m wide for the shellfish. The number of buoys will be gradually

increases according to the growth of organisms.

Polyethylene rope of about 3m length is used for hanging oysters. The hanging space is about 0.8-1m for the shellfish, but when the oyster and scallop are cultured in a lantern net the hanging space is 1.2-1.5m. The hanging space is about 1-1.5m for the

seaweed. There are 30-40 kelp hung on each seed rope of about 2.5m lenght. The position of seaweed and shellfish cultivation relates to the local current conditions allowing for the flow of nutrient into the site. When the seaweed and shellfish are

cultured in the same raft, the structure of the raft follows the seaweed raft. The space between the 2 lantern nets is 2.3m with 43 units per 100m backbones.

The two informative videos below give details and describe the journey in the bay to become a global demonstrator for IMTA. The Story of Sanggou Bay from the YSLME project details the case IMTA study, and The Story of Sanggou Bay is a documentary by CCTV

that talks about the application of IMTA.

https://www.open.edu/openlearncreate/pluginfile.php/589832/mod_page/content/28/the%20Story%20of%20Sanggou%20Bay.mp4Video player: the%20Story%20of%20Sanggou%20Bay.mp4

The Story of Sanggou Bay - by CCTV