Socio-economic assessment

Socio-economic Assessment

IMTA is the co-cultivation of fed species together with extractive species which may feed on the organic and inorganic effluents generated by the fed species, and in the past few years interest in this field has risen considerably in line with the intense efforts of identifying sustainable solutions in all industries. In this respect, the economic viability needs to be thoroughly explored, so as to motivate aquaculture industries to invest in them. FAO recently recognized, among others, the need to strengthen the use of new technology, such as IMTA systems supported by electronic monitoring and reporting, taking into account the 2021–2030 United Nations Decade of Ocean Science for Sustainable Development.

Here we address the financial aspects and the cost effectiveness of such new integrated cultivation systems. Outcomes come from the cost effectiveness analysis and the critical review of the available literature, and pilot site experiences. These are outlined in the following:

Such systems allow harvesting not to be dependent on one species and taken that the market value may be subject to change, the security of the farm increases by the co-cultivation of seabass, mussels and seaweed. The capacity factor of processing plants can also be improved by multi-processing of several seaweeds from various seasons.

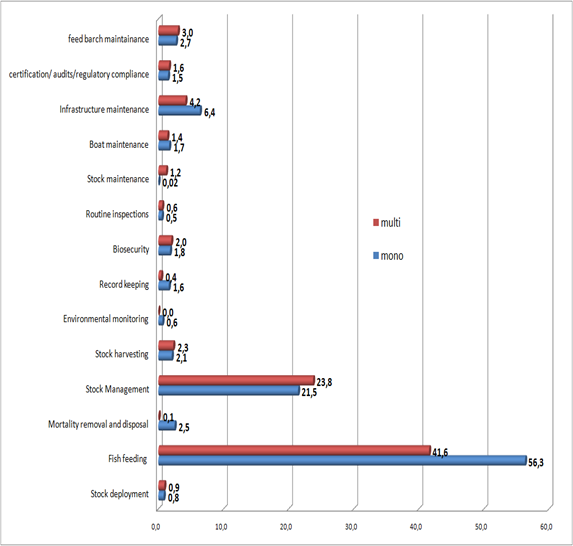

The application of activity-based model revealed that multitrophic conditions provide considerable time savings for the personnel to be engaged with other species. In other words, economies of scale and efficient labour management is one of the most significant outcomes of the Activity based Resources Allocation model (ABRA) application in the IMPAQT project.

Involving all cost elements in the analysis results in increased total operational costs due to additional consumables put in the system (bag & ropes for mussels, nets & ropes for seaweed, sensors damage & maintenance). The development of robust cultivation systems, with a high degree of standardisation of the harvesting process will likely reduce operational costs further.

Figure 1. Monoculture vs Multi-trophic labour hours for Seabass (CAMLI)

In terms of net profit overall, comparing total operating costs with turnover it can be concluded that mainly because of the production volumes increase, the later exceed costs, however the analysis didn't include depreciation cost of capital, marketing and storage costs, which are important to consider.

On the other hand, after the COVID-19 pandemic era and the climate of uncertainty in the European fish market, prices in the fishery and aquaculture sector are expected to rise. This, together with the improved survival rates provided by the IMPAQT platform and the increasing positive public attitudes towards IMTA and premium sustainable products, can further increase the profitability of adopting IMTA.

A critical issue that also has to be taken into account is that IMTA infrastructure for co-cultivating finfish with seaweed and mussels require additional area, which may be restrictive. In this sense, discussions with industry veterans and researchers revealed that salmon farmers on Canada’s east coast would not be willing to reduce their total salmon production to accommodate IMTA since salmon is too valuable for existing operators (Food and Agriculture Organization of the United Nations, 2016).

Because of the interdependencies between system design, production, processing, economic performance and environmental impact, it is strongly recommended to continue the cooperation between all knowledge institutes, involving larger scale deployments, for more representative and reliable results.

The socio-economic assessment and cost-effectiveness analysis reveal the positive prospects of the IMTA systems through collaborative action for the promotion of sustainable fishing practices. They contribute to the sufficient understanding of the critical factors in the area of efficient resources management in an IMTA environment, since the activity-based method allows the effective re-engineering of the activities and their continuous improvement.