2.2.5 Using insulation

Loft insulation

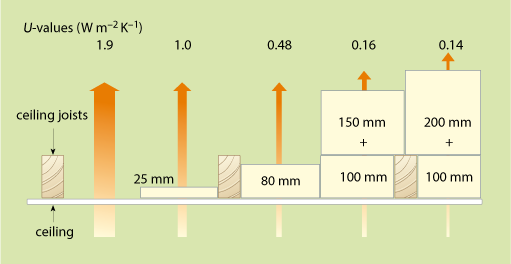

The most familiar use of wool-type insulation is in loft insulation. Since its first introduction into the UK Building Regulations for housing, the recommended thickness has increased from 25 mm in 1974 to 270 mm at present (2023) for both new build and for existing houses. Figure 10 shows the U-values resulting from different thicknesses.

Loft insulation is usually sold in rolls. A ‘base layer’ of 100 thickness is rolled out between the wooden ceiling joists (Figure 11) and then a further layer 170 mm thick is added over the top, blocking the upward heat loss through the ceiling joists. This is likely to achieve a U-value of about 0.15 W m-2 K−1, a twelve-fold improvement compared to an uninsulated loft.

It is important to make sure that any insulation does not block gaps at the roof eaves, to allow air movement within the loft space (see Section 2.3). Insulation should be omitted under any water tanks in the loft space to allow heat from the house to reach them. They, and any water pipes in the loft space, should be properly insulated to make sure they don’t freeze in winter.

Cavity wall insulation in existing buildings

The walls of buildings can be insulated in many ways. In existing buildings with cavity walls insulation can be inserted into the cavity as long as the building isn’t exposed to high winds with driving rain, since the main function of the cavity is to stop damp penetration through the wall.

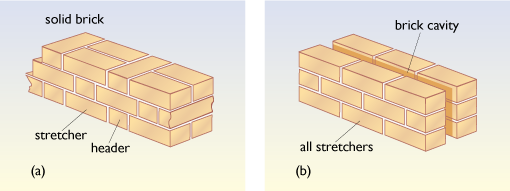

All brick walls may at first sight look the same, but on closer inspection the outer skin of a cavity wall, as shown in Figure 12, will be seen to be made up of bricks all laid side-on (stretchers). A solid brick wall will also include bricks laid end-on at right angles (headers).

Holes can be drilled in the outer brick skin and foam insulation can be injected into the gap, or rock wool or polystyrene beads can be blown into it. Typically this will improve the U-value from about 1.5 W m–2 K–1 to about 0.6 W m–2 K–1.

Internal insulation of existing solid walls

A typical solid brick wall two bricks (about 230 mm or 9 inches) thick has a relatively poor U-value of 1.4 – 2 W m-2 K-1. Such solid walls can be ‘dry lined’. This involves putting a layer of insulation on the inside faced with plasterboard. This is fairly simple to do (as long as the occupants don’t mind the disturbance to the interior of the house). Sheets of foam-backed plasterboard can be glued to the wall (Figure 13(a)), or alternatively insulated battens can be screwed to the wall with a layer of insulation between them and covered with a surface layer of plasterboard screwed to the battens (Figure 13(b)).

The U-values that can be achieved are mainly dependent on how much reduction in the interior room sizes can be tolerated. For example the 2013 UK Building Regulations suggest a target value of 0.3 W m-2 K-1. This would require the use of 75 mm of polyisocyanurate foam.

External insulation of solid walls

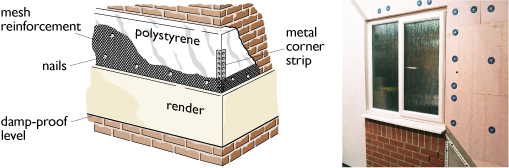

Alternatively solid walls can be externally insulated, usually with a thick layer of polystyrene foam which is then either covered with a layer of cement render or a special cladding layer (see Figures 14(a) and 14(b)).

External insulation is commonly used in the refurbishment of tower blocks of flats. Although it is relatively expensive, it is possible to achieve good U-values of better than 0.3 W m–2 K–1 with 100 mm or more of insulation. The disastrous fire in the Grenfell Tower block in London, in summer 2017, has stressed the need for the overall design of such external insulation arrangements to be properly fireproof. Also, insulation materials should not give off toxic fumes when burning or in normal use (see Latif, E. et al., 2019).

New buildings

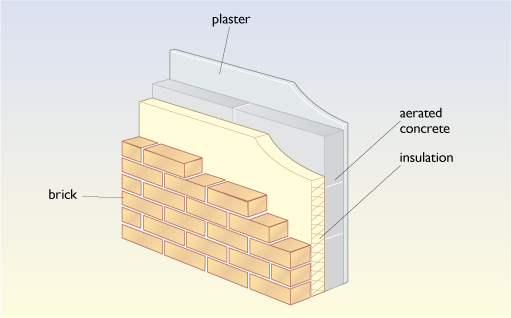

In new construction, brick walls can be built with cavities and insulation batts built in. If the building is in an area of driving rain then an air gap may also have to be included. Insulating aerated concrete blockwork can also be used to build the inner leaf (see Figure 15).

A wall U-value of 0.26 W m-2 K-1 is currently (2023) suggested by the UK Building Regulations. This can be bettered by making the cavity as wide as necessary (200 mm to 300 mm) to incorporate more insulation and, if necessary, to retain an air gap to prevent damp penetrating the wall. Timber frame construction can also use considerable thicknesses of insulation; 200 mm or more of wall insulation is commonly used in Scandinavia and Germany.

Floors

The floors of buildings can also be well insulated. Modern UK construction often uses thick sheets of polystyrene or polyurethane foam. In older buildings with suspended timber floors, sheets of insulation material can be inserted under the floorboards between the joists. The Building Regulations for England (HM Gov, 2021) suggest a floor U-value of 0.18 W m-2 K-1 for new buildings and for refurbishment projects. This is likely to require the use of polystyrene insulation more than 100 mm thick.