3.3.1 Heat pumps

Instead of generating heat by burning a fuel, a heating system can use heat drawn from the outside environment, the air or the ground, using a heat pump.

Small heat pumps are actually familiar objects. Every domestic refrigerator uses one.

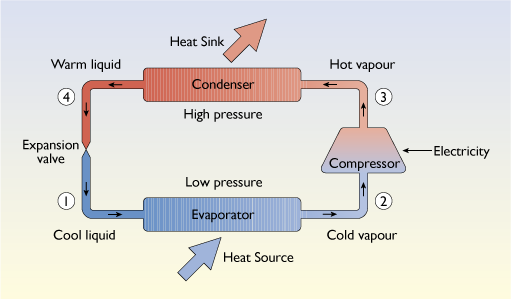

Figure 33 shows the key elements of the most basic type of heat pump.

The heat pumping process is made possible by the use of a special refrigerant liquid that boils at a low temperature at atmospheric pressure (typically about –15 ºC).

- a) At point (1) in Figure 33 this starts as a cool liquid. In order to convert a liquid to a vapour, it must be given energy – the so-called latent heat of evaporation. The refrigerant absorbs heat in a heat exchanger called the evaporator and vaporizes.

- b) At point (2) the vapour enters an electrically driven compressor that raises its pressure and temperature.

- c) At point (3) the hot vapour then enters another heat exchanger, the condenser where it condenses to a warm liquid and gives up its latent heat of vaporization.

- d) At point (4)) it is forced through a fine expansion valve or throttle where it loses pressure and drops in temperature.

It then repeats the cycle.

Overall, heat is ‘pumped’ from a low temperature in the evaporator to a higher one in the condenser. In a domestic refrigerator, the heat is absorbed in an evaporator inside the refrigerated compartment, thus lowering its temperature, to a condenser on the back of the refrigerator, where the heat is released, warming one’s kitchen in the process.

The choice of refrigerant is very important. The ‘traditional’ refrigerant, Freon-12 – developed in the 1930s and also used for blowing foam insulation – has had a devastating effect on the world’s ozone layer as well as it being a powerful greenhouse gas. Its use was banned worldwide in the early 1990s. Even the ‘replacements’ for Freon-12, hydrofluorocarbons (HFCs), introduced in the 1990s, are themselves now being replaced with alternatives, hydrofluoroolefins (HFOs) that are much less likely to contribute to global warming.

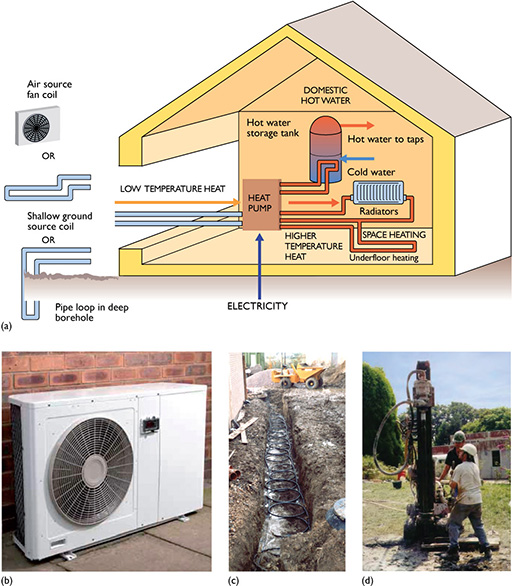

In buildings a heat pump may be used for heating or cooling (more commonly known as air conditioning). When used for heating the evaporator is located somewhere in the external environment. An air source heat pump is likely to have a fan coil unit such as that shown in Figure 34(b). A ground source heat pump uses pipes buried in the soil. These may be laid in a shallow trench, as in Figure 34(c) or in a deep vertical borehole that may be 10 metres or more deep.

Heat is then pumped from the outside environment to a condenser inside the building, normally connected to a normal central heating system, as previously shown in Figure 28. The temperature of the heat is sufficient to be useful for heating purposes. Energy (usually electrical) is, of course, required to operate the compressor.

A key performance parameter is the coefficient of performance (COP).

- COP = heat output from condenser / electrical work input

Typically 1 kWh of electricity can be used to produce 3 or more kWh of heat. This might seem to defy the law of conservation of energy, but the maximum COP is limited by the laws of thermodynamics. It is possible to have a high COP if the temperature difference through which the heat is raised is small, but the value may drop significantly if the temperature difference is large. This may be particularly true where domestic hot water has to be heated to 60 ºC in midwinter.

In order to function in midwinter, the evaporator has to be able to absorb heat from the external environment even though the external temperature may be very low (down to below –5 ºC in the UK). This requirement potentially limits the performance of air-source heat pumps. Burying the evaporator coil in the ground (or in a lake or river) provides a more stable temperature environment in extreme winter conditions and can result in higher COPs.

In an air source heat pump, the heat that is drawn from the external environment is taken immediately from the outside air, cooling it in the process. In a ground source heat pump, the same process takes place but by cooling the ground (by only a degree or two) so that heat flows down into it from the air over a large area and a long time period.

A heating system using a heat pump is likely to include fans and pumps and may require top-up direct electric heating in mid-winter. A more accurate measure of the overall performance is thus the seasonal or system performance factor (SPF). This is the ratio of the annual heat produced by the heating system to the electricity consumed. Measured SPF values in the UK have ranged from 2.2 to 4.0, with ground source heat pumps performing better than air source ones (EST, 2013). Put simply:

- Useful heating energy produced = electricity consumed × SPF

Although heat pumps driven by gas engines or absorption heat cycles have been produced, this is essentially an electric heating technology. It can be thought of as reclaiming some of the primary energy losses at the power station.

A modern gas fuelled combined cycle gas turbine (CCGT) power station can have an efficiency of 50%. It thus takes 2 kWh of gas to produce 1 kWh of electricity. However, the heat pump can turn this back into 2.5 kWh of heat.

- overall thermal efficiency = 2.5 kWh / 2 kWh = 125%

This makes it an attractive alternative to gas heating, although the total capital costs of heat pump and power station are considerable.

The heat gains from heat pumps, i.e. the difference between the heat output and the electricity input, have now been classified as a form of ‘renewable energy’ under the 2009 EU Renewable Energy Directive (CEC, 2009).

Where a ground source heat pump is being considered for a house, it is essential that the heat losses are reduced as far as possible with insulation first. Ground source coils may require as much land area as the total floor area of a house, and they can make up over half of the total installation costs.