4.1.2 Refrigerators

In domestic use a refrigerator usually has a main cabinet with a temperature of around +5°C and may have an icebox (freezer compartment) maintained at –5°C. A freezer has a lower internal temperature of around –18°C. Combinations, known as fridge-freezers, have become increasingly common in recent years.

In 2019 domestic refrigeration in the UK used an estimated 11 TWh of electricity per year, about 3% of total national demand (BEIS, 2021c). This figure is down from a peak of about 17 TWh around 1990 due to the improved energy efficiency of fridges on sale. However these figures have to be compared with the 2.5 TWh used for refrigeration by the food processing industry. This presumably handles exactly the same food and stores it for longer periods, but it does so in physically larger and more energy-efficient cold stores.

Until the 1980s there was little interest in the UK in producing ‘energy efficient’ fridges. It paid designers to maximise the internal storage space even if that meant cutting down on insulation thickness. Electricity bills were a secondary consideration. Yet the potential for saving was enormous. The average consumption for a European 200-litre larder fridge (i.e. one without a freezer compartment) in 1973 was 550 kWh yr–1. A Danish unit produced in 1988 showed that electricity consumption could be cut to 90 kWh y−1. Better insulation reduced the heat loss and an improved COP (coefficient of performance) was achieved by fitting a larger evaporator and condenser (Nørgård, 1989).

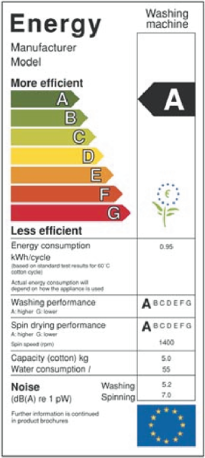

In 1994, a European energy labelling scheme was set up in part to promote low-energy fridges. The ratings of this scheme were not very ambitious and the best fridges only used half of the electricity of the worst. By 2019 it was proving easy to exceed the original ‘A’ rating and almost all manufacturers were offering A+ and even A++ models. In 2020 a new labelling scheme was introduced with ratings to match the improved energy performance expectations (see sample label in Figure 41).

The best performing fridge designs use about 25 mm of insulation thickness, while freezers use about 50 mm. Improved efficiency can always be achieved with thicker insulation. However, the external dimensions are fixed in practice by the standard units of width and height of fitted kitchens, so improved efficiency will usually mean less internal storage space. The way forward may be through the use of innovative insulation, such as vacuum insulation panels.

Vacuum insulated panels (VIP)

Sir James Dewar, a scientist at Oxford University, invented a ‘vacuum flask’ in 1892, as a container for low-temperature liquefied gases. This consisted of two glass flasks one inside the other with a vacuum in between ensuring that no heat could flow by conduction across the gap. The glass surfaces were also given a low-emissivity coating of silver to prevent heat radiating across it.

This was turned into a commercial product, the Thermos flask, in 1904 by two German glass-blowers. It has been the standard receptacle for carrying hot drinks to picnics ever since. Large flasks of up to 125 litres capacity were developed for cold food storage in the late 1920s, but were overtaken by the rise of the modern refrigerator.

The development of flat vacuum panel insulation, like that of vacuum double-glazing, is fraught with many difficulties. The most basic is that of resisting the pressure of the air. A panel one square metre in size would have to resist a force equivalent to about 10 tonnes. One approach is to take a plastic foam or an ‘aerogel’ made from silica, wrap it in a thick airtight plastic cover and pump any air or gases out. As long as the foam has sufficient strength not to collapse under the atmospheric pressure, thermal conductivities of under 0.005 W m−1 K–1 can be achieved at pressures of around 1 thousandth of an atmosphere. This represents a four-fold improvement over the best non-evacuated plastic foam insulation. There are still many problems to be solved to maintain this performance over a long period of time since any pinholes in the outer layer could destroy the vacuum. Although VIPs are now commercially available, they are expensive and there are likely to be trade-offs of production cost against life expectancy.

If this can be developed and the manufacturers’ reluctance to trade storage volume for insulation thickness can be overcome, then the fridges of 2050 could each use under 100 kWh yr–1. UK domestic total electricity use by ‘cold’ appliances could have fallen by a factor of five from its peak 1990 level to only 3.5 TWh yr–1 (Boardman et al., 2005).

Activity 15

Given that insulation is cheap, why might refrigerator manufacturers be reluctant to use thicker insulation in their designs?

Answer

Because the external dimensions of fridges are limited by the standard heights and widths of fitted kitchens. Thicker insulation will thus mean less storage space inside.