article icon

article icon

Science, Maths & Technology

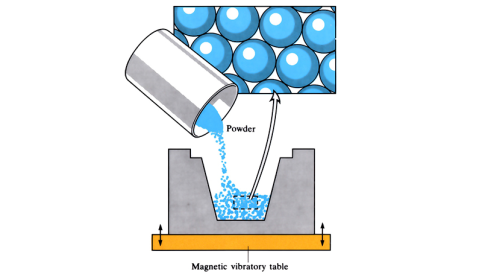

Pressureless sintering

A process where loose metal powders are poured into a metal die and vibrated until loosely compacted. When filled, the die is placed inside a furnace and sintered.

article icon

article icon

Science, Maths & Technology

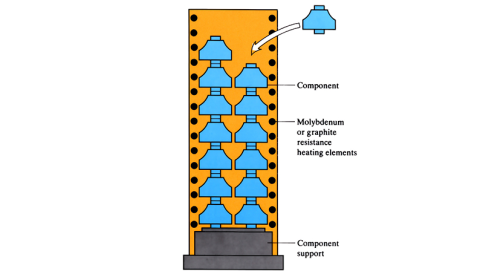

Hot isostatic pressing (HIP)

High temperature and pressure are applied simultaneously to pre-cast or sintered components. The addition of argon gas to the furnace helps to apply isostatic pressure to the component/s. The pressure and heat help to fill any pores on the surface of the component, thus optimising material properties and density.

video icon

video icon

Science, Maths & Technology

What happens when you microwave an egg?

The New Scientist team have microwaved an egg, so you don't have to. Because you really, really shouldn't.

article icon

article icon

Science, Maths & Technology

Download your free Matrix of Modern Life poster

A poster from The Open University that explores the colourful connections between different parts of science, engineering and technology - presented in the inimitable Bang style

video icon

video icon

Science, Maths & Technology

Measure the speed of light with your microwave

This video discovers an unconventional way to measure the speed of light using the microwave in your kitchen

article icon

article icon

Money & Business

How is identity data creating headaches for large companies?

Increasingly the costs and risks of holding data are turning toxic for businesses. Bhargav Mitra and Robert McCausland explain why.

article icon

article icon

Science, Maths & Technology

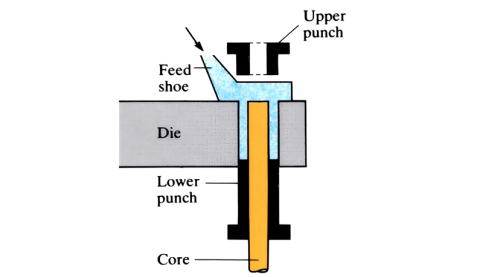

Cold Pressing and Sintering of Powders

A blend of powders is fed into a closed die, where upper and lower punches compact the powder using enough pressure to bind the powder particles together. The formed component is ejected from the die and heated at low temperature to burn off any residual lubricant. The component then moves to a protected environment where it is sintered before ...

article icon

article icon

Science, Maths & Technology

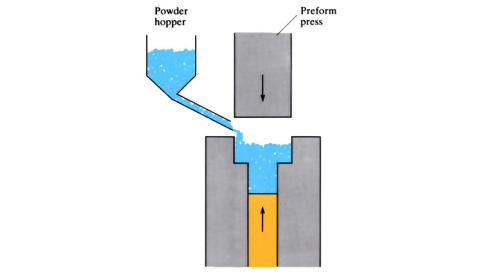

Powder Forging / Hot pressing

A custom blended mix of powders is poured into a cavity mould, and compacted under pressure into a ‘preform’. The preform is heated to forging temperature then rapidly transferred into a forging press, where it is hot pressed into the final cast shape.

article icon

article icon

Science, Maths & Technology

Slip-casting

The casting slip is a suspension of fine particles in a liquid medium. Slip is poured into a permeable mould, where liquid is drawn out of the slip, via a capillary action. A layer of solid slip (‘clay’) remains adhered to the walls of the mould. Once the required wall thickness of the casting has been achieved, the residue liquid is drained out...

article icon

article icon

Science, Maths & Technology

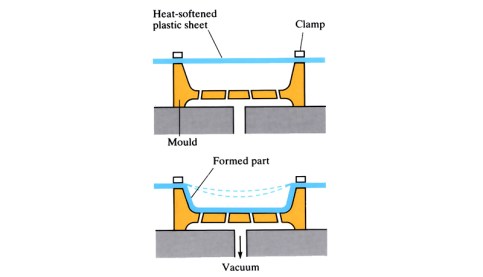

Vacuum Forming (Thermoforming)

A sheet of plastic, softened by heat, becomes pliable and when placed under vacuum adopts the shape of male or female mould.

article icon

article icon

Science, Maths & Technology

Why do volcanoes erupt?

What forces create these geological timebombs?

article icon

article icon

Science, Maths & Technology

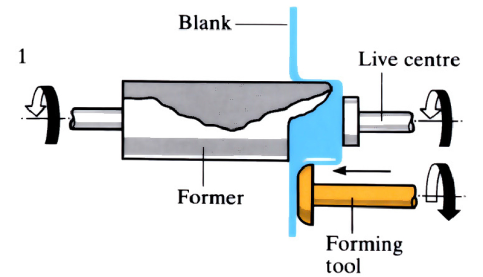

Metal Spinning / Flow Turning

Spinning is a process used to produce an axis-symmetric hollow shape by the application of lateral pressure from a forming tool, to a rapidly revolving circular blank of sheet material, causing it to assume the shape of a former that is rotating with it.