article icon

article icon

Science, Maths & Technology

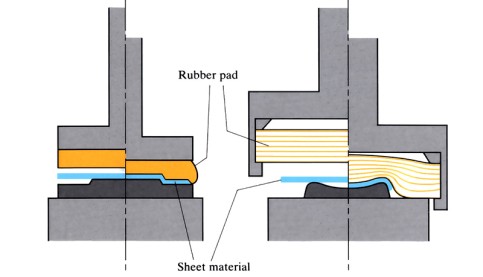

Fluid and Rubber Die Forming (Guerin and Hydroform)

Sheet metal is placed between a solid die and a rubber pad. Under pressure from a rigid tool, the rubber behaves like a liquid and forms over the shape of the die, forcing the sheet metal to also adopt the die shape.

article icon

article icon

Science, Maths & Technology

Explore systems thinking with OpenLearn

Get to grips with systems thinking - dip into our wide range of resources here on OpenLearn

article icon

article icon

Science, Maths & Technology

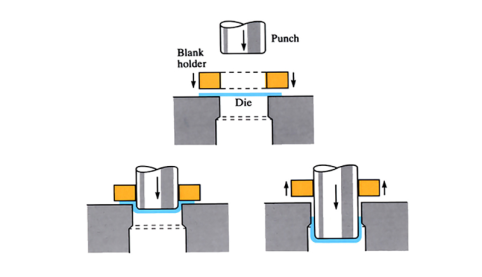

Deep Drawing

A sheet blank, subjected to a peripheral hold-down pressure, is forced by a punch into and through a die to form a deep recessed part, having a wall thickness substantially the same as that of the blank.

article icon

article icon

Science, Maths & Technology

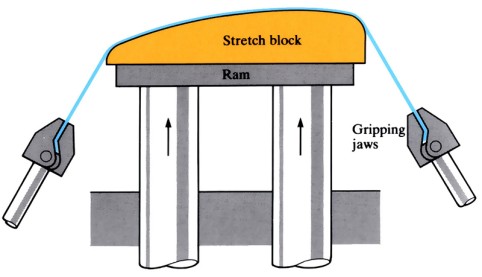

Stretch forming

Contoured, curved shapes are formed from sheet metal pressed, stretched and bent over a die. Typical applications include curved panels such as car door panels or wing panels on aircraft.

article icon

article icon

Science, Maths & Technology

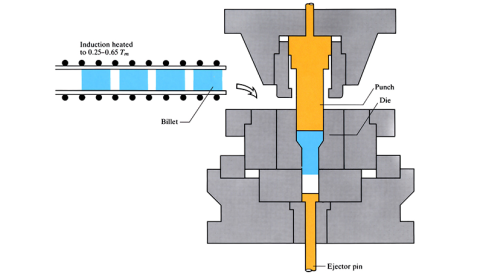

Warm forging

The workpiece billet is heated to temperatures between 0.25 and 0.6 Tm. A close fitting punch is used to exert pressure on the malleable metal billet held in a heated, closed die until forged to the required shape.

article icon

article icon

Science, Maths & Technology

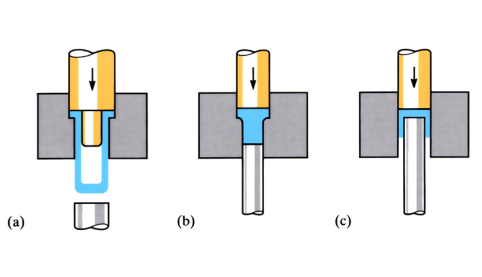

Cold forging

A forging process carried out at temperatures below 0.25Tm. A closely fitting punch is used to exert pressure on malleable metal held in the die.

article icon

article icon

Science, Maths & Technology

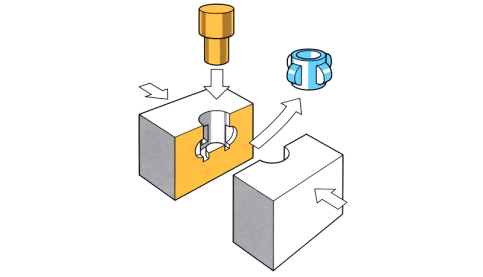

Axiforge process

Axiforge process can be carried out on dies, positioned on vertical or horizontal axes, within a press. Sideways ram movements apply pressure to the outside of a split die, so that the two parts close around a heated billet, forming it into the required external shape. This is followed by pressure from one or two piercing punch(es), which pierce...

article icon

article icon

Science, Maths & Technology

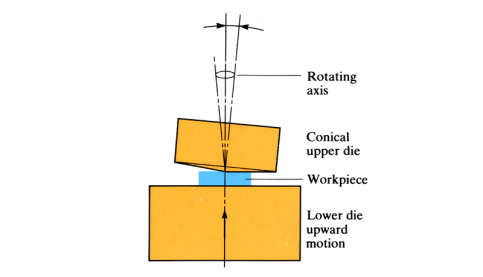

Orbital forging

Workpiece material is forged between two dies. The bottom die moves upwards whilst the top die, tilted to a preset angle, rotates (orbits) around the central axis, progressively forming the malleable material into the required shape.

article icon

article icon

Science, Maths & Technology

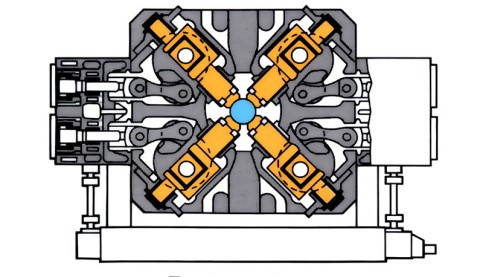

Rotary Forging, General Forging Machine (GFM) and Swaging

A circular housing contains a rotating shaft (rotor) holding free moving anvils. At the end of each anvil is a die. The dies surround a centrally placed workpiece. Revolving around the rotor is a cage holding loosely rotating rollers. As the cage rotates, the rollers impact on the anvils, which effectively hammer the stationary workpiece into ...

article icon

article icon

Science, Maths & Technology

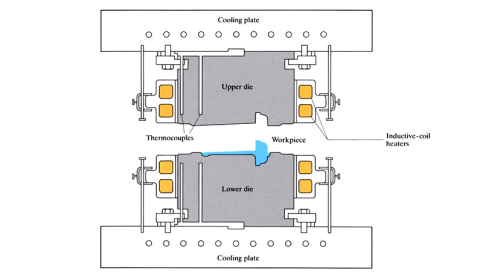

Isothermal precision forging

The workpiece is formed to shape at a slow rate and at a temperature almost equal to that of the heated die. The long forging time, alongside forces exerted by the die, help to form an almost ‘ready to use’ component needing minimal supplementary machining.

article icon

article icon

Science, Maths & Technology

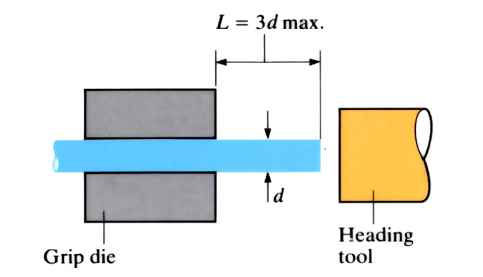

Upset forging

A heading tool or ram is positioned perpendicular to the cross sectioned end face of a rod or bar gripped in a die. On application of pressure, the length of the rod is reduced and the diameter is increased (upset). This manufacturing process is used extensively in the production of fasteners, to form bolt heads, screw heads etc.

article icon

article icon

Science, Maths & Technology

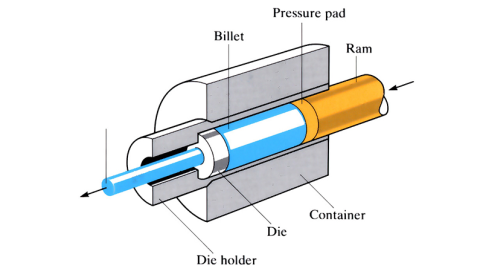

Hot extrusion

A ram forces a heated billet to flow through a shaped hole in a die. Can be forward, backward or hydrostatically extruded.