article icon

article icon

Science, Maths & Technology

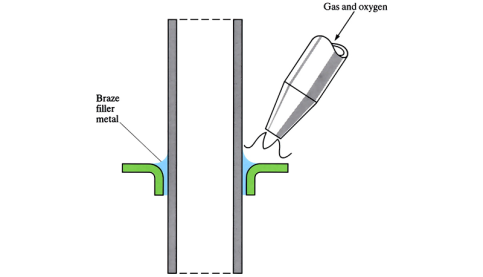

Brazing

The workpiece material is not melted as in welding, but metal parts are joined using filler metals that have a melting point above 450°C, but below the melting point of the materials being joined. The molten filler metal is drawn into the weld gap by capillary attraction across the joint, eventually solidifying to form the bond. There are ...

article icon

article icon

Science, Maths & Technology

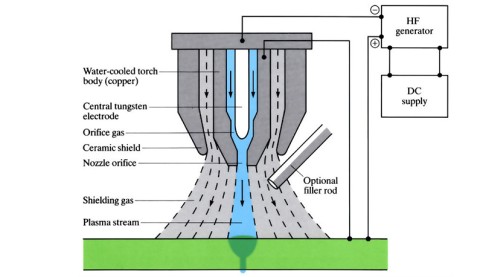

Plasma arc welding

Welding is initiated by an electric arc transferred from a torch body to the workpiece, via a high temperature, high velocity plasma jet forced through a constricting nozzle. Hence, delivering a high concentration of heat to a very small area, to melt the weld material and fuse the weld joint.

article icon

article icon

Science, Maths & Technology

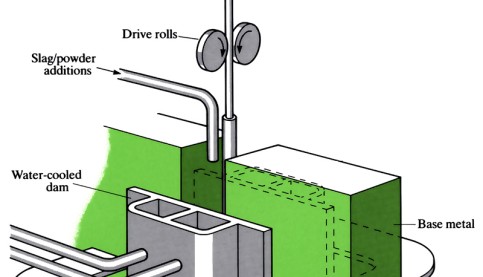

Electro-slag welding

Heat is generated by an electric current, via flux covered electrode wire, which passes through conductive liquid slag sitting in the weld gap. Melted material from the workpiece amalgamates with molten flux, to form the weld joint.

article icon

article icon

Science, Maths & Technology

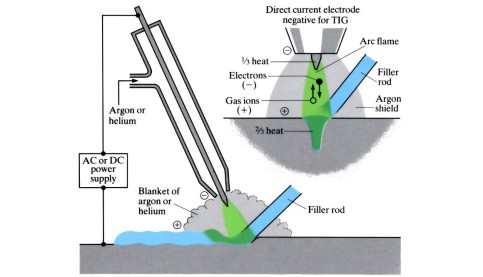

Gas shielded arc welding processes (TIG/MIG/MAG)

Welding is initiated by an electric arc between a tungsten electrode and the metal to be joined. The arc melts the metal, whilst shrouding it in a cloud of argon, helium gas or carbon dioxide, to shield the weld from contaminants in the atmosphere. Extra filler metal can be added by using a separate filler rod.

article icon

article icon

Science, Maths & Technology

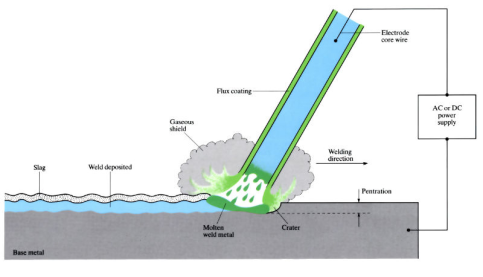

Manual metal arc welding (MMA)

Welding is initiated by striking an electric arc between a flux coated electrode and the metal workpiece to be joined. A combination of melted base metal, and molten core wire from the electrode, forms the welded joint. Welding materials are shielded from contaminants in the atmosphere by gases produced from the flux coating.

article icon

article icon

Science, Maths & Technology

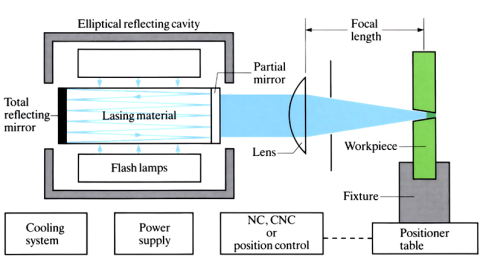

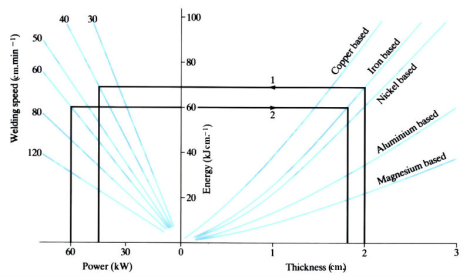

Laser beam welding

Heat is generated by a concentrated, high energy laser beam directed at the joint to be welded. The surfaces of the workpiece melt, bonding the two parts together. Results in a narrow weld zone and HAZ. Combining laser and gas tungsten arc (GTA) welding can produce deeper weld penetration.

article icon

article icon

Science, Maths & Technology

Electron beam welding

Heat is produced by a high energy beam of electrons directed at the joint to be welded. Heat transfer is very localised, not by surface conduction, but within the workpiece itself, so no filler is required. Results in a narrow weld zone and HAZ. Process carried out either under vacuum, or non-vacuum.

article icon

article icon

Science, Maths & Technology

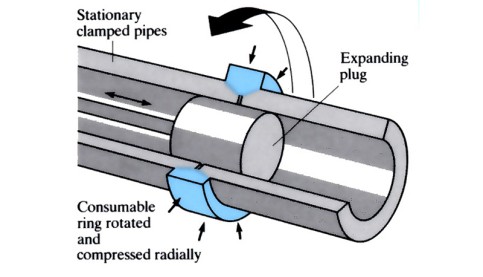

Friction welding

By rotating one part against a fixed second part, friction occurs. The heat resulting from friction leads to plasticity in the material, then by administering controlled compressive pressures, the two parts are welded together.

article icon

article icon

Science, Maths & Technology

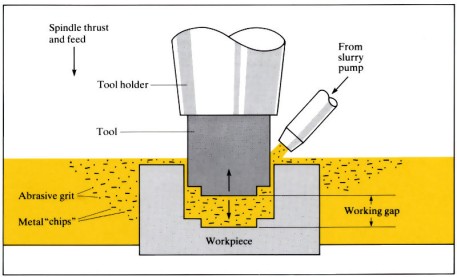

Ultrasonic machining (USM)

The workpiece is held in a tank of slurry containing abrasive particles, the slurry is injected into the space between a vibrating tool and stationary workpiece. Material is abraded away until a mirror image of the tool is cut into the workpiece.

article icon

article icon

Science, Maths & Technology

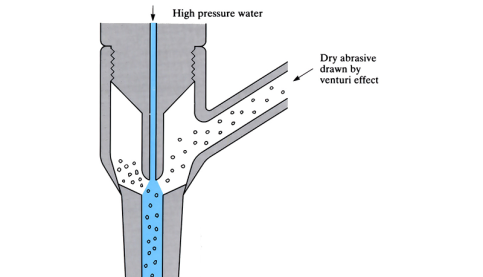

Abrasive jet cutting

A high pressure, high velocity jet of water (or air), mixed with dry abrasive particles to form a slurry, is forced through a nozzle in the cutting head. The jet impinges on the surface of the workpiece, eroding away material.

article icon

article icon

Science, Maths & Technology

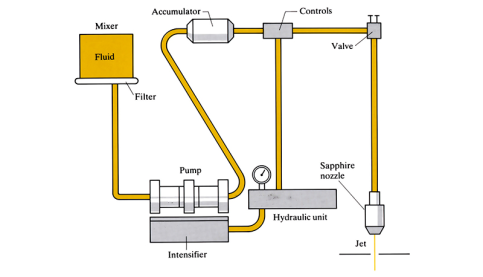

Water jet cutting (Hydrodynamic cutting)

High velocity, high pressure water jets (or a mixture of water and an abrasive) are used to cut into the surface of the workpiece. Used mainly on non-metallic thin sheet material.

article icon

article icon

Science, Maths & Technology

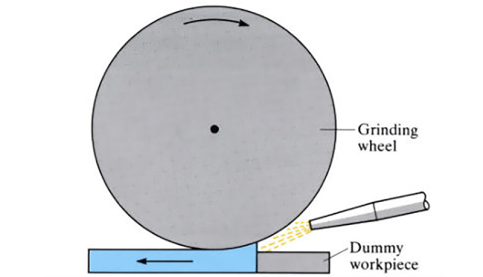

Creep feed grinding

Effectively a milling process, as high volumes of material can be removed, producing deeper cuts, in a single pass of the grinding wheel. Final surface finishing of the workpiece is provided during a second pass of the grinding wheel, which has by then been dressed by a small diamond roller. Chips of workpiece material are washed away by a jet ...