article icon

article icon

Science, Maths & Technology

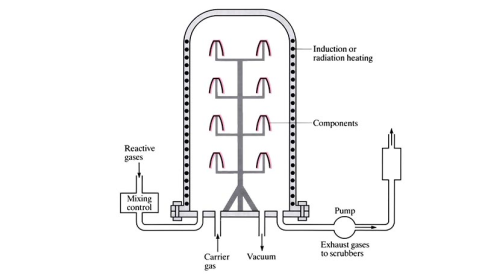

Chemical vapour deposition (CVD)

Reactive gases are fed into a heated chamber containing the component(s) to be coated. At elevated temperature, various gaseous phases chemically react with the heated surfaces of the component(s), and a solid, corrosion resistant coating is deposited onto those surfaces.

article icon

article icon

Digital & Computing

From Zero Day to Doomsday – Public Lecture

We are delighted to invite you to From Zero Day to Doomsday, a lecture by Mike Richards on the WannaCry ransomware cyber-attack, which had serious implications last year for the NHS and businesses around the world.

article icon

article icon

Science, Maths & Technology

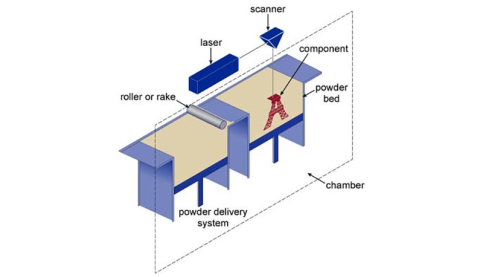

Selective laser melting (SLM)

Heat is generated using a focused heat source, normally a laser, sufficient to melt a thin layer of powder applied to the surface of a substrate. Material is added layer by layer by lowering the build by a small amount and spreading a thin layer of powder over the surface. To create the desired geometry, the heat source is traversed over the ...

article icon

article icon

Science, Maths & Technology

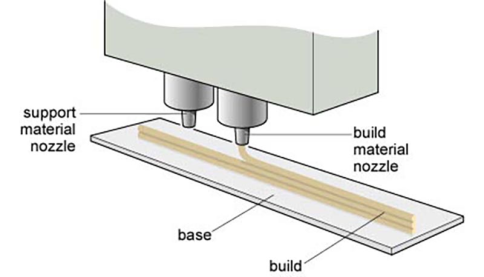

Fused deposition modelling (FDM)

Thermoplastics are heated to above their glass transition temperature and extruded onto a substrate to produce a raised track or filament. The desired geometry is created by manipulating the extrusion nozzle using a computer-controlled positioning system. Three-dimensional structures can be formed by adding material onto previously deposited ...

article icon

article icon

Science, Maths & Technology

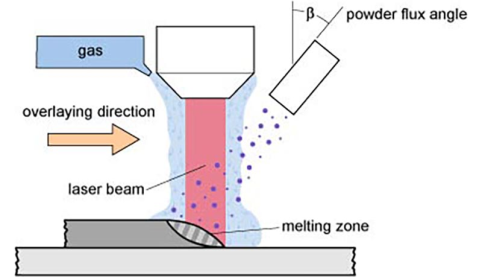

Direct metal deposition (DMD)

Heat is generated using a focused heat source of various kinds, sufficient to melt the surface of the substrate and form a small melt pool. Material is added to the melt pool using a focused powder stream or a wire feed system to form a raised portion of material. To create the desired geometry, the substrate is manipulated using a ...

article icon

article icon

Science, Maths & Technology

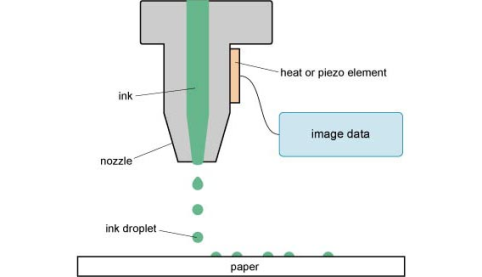

3D printing

Although often used as a blanket term for additive manufacturing, 3D printing is a technique where a print head is used to control the deposition of polymer on a substrate drop by drop.

article icon

article icon

Science, Maths & Technology

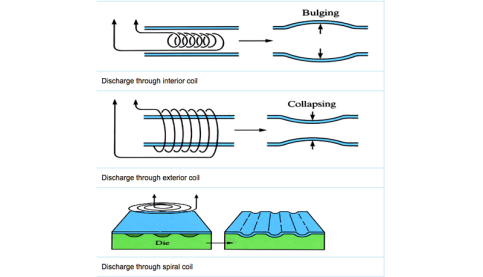

Magneform (electromagnetic assembly and forming)

A high energy rate, cold forming technique that reshapes metals without physical contact. When an electric current generates pulsed opposing magnetic fields near the metal, a controllable pressure is created.

article icon

article icon

Science, Maths & Technology

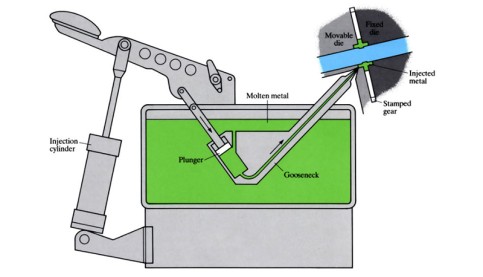

Injected metal assembly (Liquid riveting)

This refinement of die casting is a simple joining/assembly technique where components are accurately positioned and metal is injected into the cavity between the components and a die, solidifying almost instantaneously. The join, which may be stronger than the component itself, depends on the mechanical locking action and shrinkage of the ...

article icon

article icon

Science, Maths & Technology

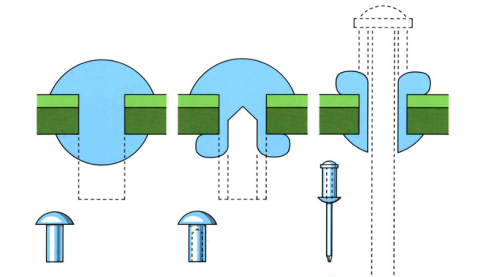

Fasteners

Mechanical joining using hardware devices to fasten two or more parts together, e.g. nuts and bolts, screws, rivets or mechanical interlocks.

article icon

article icon

Science, Maths & Technology

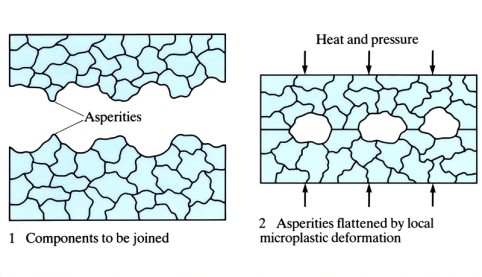

Diffusion bonding (SPF/DB or form bonding)

A solid state welding process where two surfaces are bonded together, over time, using heat and pressure, usually under vacuum or inert gas to avoid contamination. Used for metals that are hard to weld by conventional fusion welding. Filler metal is not needed, because atoms from each surface diffuse into each other to create the bond.

article icon

article icon

Science, Maths & Technology

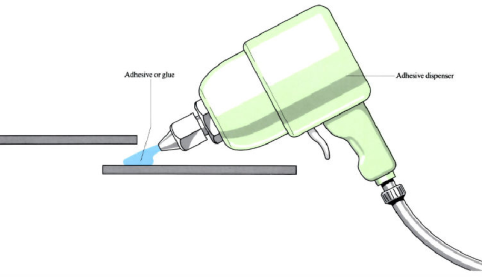

Adhesive bonding

Adhesive bonding uses an adhesive material, or glue, to join a wide range of dissimilar materials. The glue does not generally react with the materials being bonded.

article icon

article icon

Science, Maths & Technology

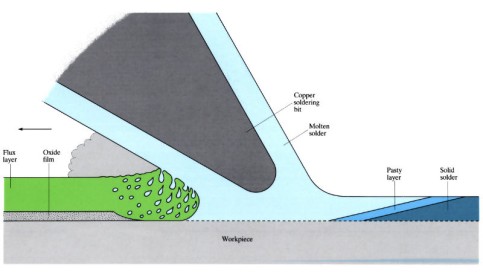

Soldering

The workpiece material is not melted as in welding, but metal parts are joined using filler metals that have a melting point below 300°C. The molten filler metal is drawn into the weld gap by capillary attraction, eventually solidifying to form the bond. There are various ways to apply the heat.