5.14 Questions remain and myths persist

So ended the enquiry, with reports that condemned the design and construction of the bridge. However, the speed of the enquiry – only 6 months – left many gaps in the evidence. They included:

a detailed survey of the damage to the cast-iron piers that fell into the river, pinpointing the exact position of casting and other defects;

exploration of the way the original design was made, and the modifications to the design after construction was under way;

a full discussion of the material testing evidence of Kirkaldy.

Some of the destroyed piers showed columns that had clearly fallen to the west rather than the east (Figure 45), suggesting a more complex collapse mechanism than simple toppling. Were the remains of all the piers that had fallen into the river ever located and mapped? Or retrieved and examined?

Today, investigators would complete such a task so as to provide a complete picture of the disaster. Indeed, searching for all remains of structures – especially aircraft – destroyed in a disaster is one of the factors that has lengthened the time of enquiries held nowadays. They are collected and re-assembled so as to enable a reconstruction of the sequence of events.

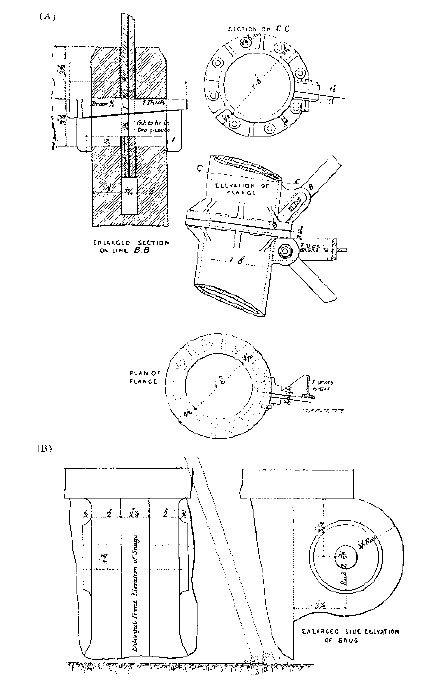

The extant remains of the piers on their platforms show that there were design modifications to the castings, such as the ‘piano’ flanges on the columns shown in Figures 25 and 26. They were jacking columns used to raise and position the girders during construction. There is also evidence the design of the flanges changed with time. Figure 48 shows a flanged column joint that was apparently never used in the bridge piers: why was the design changed and by whom?

No original design calculations were ever produced to the enquiry, so had any been performed at all? Pole and Stewart implied such calculations had been performed but were not sufficient for their own report, so they performed their own de novo (from new).

The material-testing results by David Kirkaldy were critical in establishing the weakness of the lower single lugs, but he was never called to give evidence himself and the court relied on Henry Law to present the results. Kirkaldy could have explained the scatter in the results: were they due to machine errors or deviations in the structure of the lugs, for example? Were there any casting defects in the lugs chosen by Henry Law for testing? One lug had already broken when it came to testing, but we are not told why it was broken (Paper 2, page 1x). Kirkaldy does not give us the reason for lugs being ‘unsound’ (final column of table of results on page 1x of Paper 2).

Click 'View document' below to open Paper 2 (7 pages, 4 MB).

View document [Tip: hold Ctrl and click a link to open it in a new tab. (Hide tip)]

No sketches of fracture surfaces from the broken lugs have been preserved, although it is known that Kirkaldy did produce such maps in other cases. Why was he not asked to examine fractured lugs from the bridge, which we know were collected by Law and shown to the enquiry? Some of the fracture surfaces we now have from the blow-ups of the pier photographs, for example, appear to show what could represent traces of slow fatigue crack growth, a possibility that was not even discussed at the enquiry, despite the fact the phenomenon was already known in railway vehicle axles from work by Wöhler in 1867.

The possibility of fatigue cracking of the lugs could change the picture of the disaster entirely (as Input 10, linked below, discusses in more detail). Because if it had occurred under the repeated racking of the piers in the two years prior to the final failure, the lugs would have been weakened way beyond that expected from the stress concentration effect noted earlier. The storm, in other words, was simply the final trigger to catastrophic fracture of the lugs. If there had been no storm, the bridge would have inevitably collapsed as the cracks grew to criticality.

Click 'View document' below to open Input 10

Question 17

What further work would be needed to test the hypothesis of fatigue failure at the lugs of the bridge? Supposing the possibility of fatigue cracking is confirmed by further research, how would it change our current perception of the way the bridge failed? Was the catastrophe preventable? What tests could have been arranged during the design phase of the bridge to ensure fatigue failure could not occur? Does the theory shed any light on earlier disasters? What instructions might you have given to Mr Noble if you had been aware of the researches of Herr Wöhler?

Answer

Further work to explore the fatigue hypothesis could include:

a complete survey of all existing photographs of pier platforms;

close inspection of all fracture surfaces shown in the pictures;

enhancement of the computer scans of the existing known suspect fractures.

At the same time, it would be useful to determine the history of the bridge from completion and its first serious loading by trains through the two years or so till it failed catastrophically. It should be possible to determine from railway timetables of the NBR exactly how many trains used the bridge per day. From such data, it is possible to determine the number of loading cycles to which the piers of the high girders were exposed. Further work on the stress experienced at the lugs on the wind bracing tie bars might indicate the possible stress levels at the lugs and hence the likelihood of fatigue failure.

If confirmed, the fatigue hypothesis changes fundamentally currently accepted views of the way the Tay Bridge failed. Far from being blown over by a strong gale, the bridge was seriously flawed by the time of the disaster. It collapsed because fatigue cracks had grown to a critical condition, and only awaited a final loading before failing totally. Even if the storm had not occurred, failure would have been inevitable with further use and growth of the critical cracks in the lugs. Fatigue cracks grow slowly with time and number of cycles, but they grow steadily until they reach a critical size and then grow suddenly.

The failure was preventable because the importance of fatigue was already known from the work of Wöhler published in English in Engineering magazine. Perhaps the importance of the phenomenon was not widely accepted by practising engineers. Testing of the key components during the design and construction phase should have revealed the weakness of the tie bars and the critical bottom single lugs. Kirkaldy could clearly have performed simple tension tests for Bouch, but no such tests were performed. Whether or not he could also perform fatigue tests is unknown.

The suggestion could shed some light on the Dee bridge disaster because the cast-iron beam failed suddenly when loaded by the train that fell. The beam fractured near the centre of its span, where the load was greatest. Two diverging cracks started at the lower tension face. Unfortunately, no fracture surfaces survive, so the suggestion remains entirely academic. However, the inspectors made significant comments about the ‘repeated use’ weakening the material (Input 6).

Even without the detailed knowledge of fatigue published by Wöhler, Mr Noble should have been instructed to survey all parts of the bridge, and not just the foundation piers. He should have told Bouch about the chattering tie bars, but apparently thought he could solve the problem himself by hammering shims into the joints. Nevertheless, he certainly told Bouch about the cracked columns, who arranged for them to be mended. However, if the work of Wöhler was known, instructions should have been given to examine all highly stressed parts of the bridge that might be susceptible to fatigue. It is true that the hairline cracking found in fatigue is generally difficult to spot, but a simple test on very visible components such as the lower lugs by rubbing them with fine chalk or whiting, could reveal their presence. Larger cracks were found on some columns, initially by the painters, but hairline cracks could easily have been painted over and missed. The possibility of fatigue cracking clearly re-opens the debate about the causes of the Tay Bridge disaster, and as is usual when new light is shed on a past disaster, there are more questions than answers.