Loosening of tie bars

On Monday, 19 April, when the sitting had been moved to Westminster, such comment received dramatic but indirect support from the man put in charge of maintaining the fabric of the bridge after completion and up to the disaster, Mr Noble. Although much of his time was spent examining the pier foundations, which involved measuring the depth of water, questions were asked about the piers:

11,404. Leaving the foundations, let us go up a little bit, Did you discover whether any of the ironwork of the bridge was getting unstable or loose? – In taking those soundings that I have spoken of, I noticed or heard a chattering of the bars.

11,405. You heard them moving or shaking? – Yes.

11,406. Was it in the lowest tier of bars nearest the stone work that you found the bars chattering? – Generally. as far as my remembrance goes, it was something like the third or fourth tier down. I cannot positively say: Such a thing might have taken place in the second tier from the top to the bottom.

11,407. Speaking from the best of your recollection, can you say whereabouts in any of those piers or columns, not the supports, you first observed that any of those bars were too loose? – I cannot speak from recollection.

11,408. Were those loose bars within the high girders or without the high girders, or both? – They were both.

11,409. Did you examine the bars in order to see what was the matter with them, or whether they needed any repairs? – Yes.

11,410. Tell me what it was you found to be wrong with the bars on your examination of them? – I do not know whether I can explain it to you. I found that the cotters in coming together had got a little loose – there was not a sufficient width to get a good grip, and they had got a little loose.

…

11,416. How loose were they? – Had they been loose of course they would have been found at sight. We had to go and find out where this chattering motion took place, and then through the cotters to see which was loose, which showed me that they must have been just about as tight as this. In sounding them with a hammer we found that they were not tightened up sufficiently. In driving them home we found that they were scarcely wide enough to get a tight grip.

…

11,419. Did you find that you could drive them home tight easily with the hammer? – I found out that I could drive them home tight with the hammer on account that they were not wide enough in those places where I found them.

11,420. Then the cotters were too small for the slot-holes you think? – Yes, in those places.

11,421. No amount of driving would have made them catch each side of the slot-hole so as to make them tight? – Not properly.

11,422. Would any amount of driving have made them tight in the slot-hole in the first instance? – Not those cotters.

11,423. Then it comes to this – that from the outset those cotters were too small for those particular slots? – That is my opinion.

11,424. It was not careful work you think? – I should not think so.

11,425. Did you report what you had found to anybody? – No.

11,426. Why? – Because I thought I could remedy it.

…

11,431. What was the use of those cotters? – To tighten up the bracings.

11,432. What was the purpose of having the bracings tight? – To make the bridge stable.

…

11,438. But you thought it a sufficiently important thing to induce you at once to repair it? – Where I heard a noise from the jingling of the bars I tried to remedy it.

The answers were clarified in cross-examination, and more details of the location of the ‘chattering’ were forthcoming. The phenomenon was observed in all parts of the bridge, including the high girders, and was noticed when a train was passing.

Although Mr Noble was apparently not instructed to inspect the columns, he took it upon himself to investigate the problem and correct it. Although the tie bars were meant to be tensioned by hammering in the cotters, he found that the joints of more than 100 tie bars had become loose, presumably as a result of the movement of the bridge caused by passing trains and also perhaps by wind action against the superstructure.

He purchased lengths of wrought iron strip (0.5 × 0.25 inch in section) with which to pack the joints, and by hammering back the cotters, make them more secure. The exact number of joints so treated may actually have been rather greater than his first estimate, because the amount of iron bought could make more than 120 such shims. Much of the work had been done in late 1878, but continued into late 1879. He did not specify which joints he adjusted, although he did suggest they were ‘the third or fourth tier down’. Mr Law's evidence shows joints were also loose on the lowest tier as well, and had been jammed by Noble.

In addition he had spotted at least three cracked columns. They were longitudinal cracks and one extended 6 feet 6 inches up one of the 15 inch columns in the high girders piers. They had been strengthened with hoops of wrought iron bolted around to prevent complete failure. In one case, four such hoops had been applied.

Question 9

To what could you attribute the chattering of the joints in the tie bars noticed by Mr Noble when a train was passing overhead? Refer to Question 7 and Figure 18 when attempting to formulate your response.

What does the chattering show in terms of the lateral stability of the structure? What corroboration is there for sideways oscillation of the bridge?

Answer

As shown in Question 7, there is a backlash of about 0.5 inch in the cottered joint. So even when the joint is set up tight, a swaying movement of the pier could remove the tension, take up the backlash and put the bar with compression with an accompanying impact between the bulk of the cotter and the cut-out in the sling plates. This could be the source of the chattering.

The cottered joint is fundamentally insecure because there is nothing, apart from paint and friction, to stop the cotters loosening in their slots. This is likely to occur during chattering, when the joint is not under sufficient tension to retain the cotters by friction.

If the chattering had occurred in the east-west diagonal tie bars – the so-called wind braces – it would indicate lateral motion of the structure. Unfortunately, he did not specify which joints he mended. On the other hand, the joint is at the base of each column, so any movement at the base is likely to be more severe than looseness higher up the tiers of the pier.

Corroboration for side-to-side motion of the bridge comes from the witness evidence of the painters. They observed lateral oscillations, and they needed to secure their paint pots with every passing train. A joiner working on the bridge also noticed the oscillations, which alarmed him. When pressed by Colonel Yolland, he thought the movement could have been between 2 and 3 inches laterally at the top of the piers.

Question 10

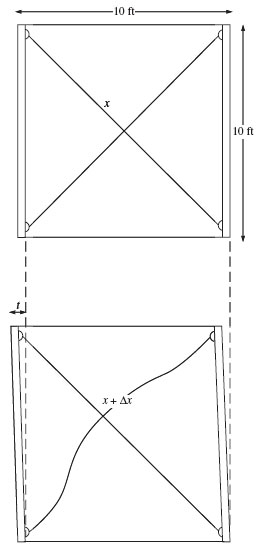

Figure 43, below, shows the dimensions of a centre cell of a tier on the east-west part of the lowest part of the pier, where the height and width are 10 feet. Based on the estimate of Question 7, calculate the effect of any looseness in the tie bar joint on the extent of sway at the top of the pier.

Assume the bolts are 1.125 inches diameter and fit a 1.25 inch bolt hole at the lugs. Any sway (horizontal movement t at the top of the cell) is simply given by 1.414 times any change in the diagonal distance (∆x).

How does your figure compare with any figures for sway produced in evidence for the BoT enquiry?

Answer

If there is a clearance of 0.0625 inch (sixteenth) between the bolts and the holes in the lugs, there will be an additional backlash of 0.125 inch (eighth) at each end of the bar. Together with the backlash of 0.5 inch from the joint, the total backlash possible in a diagonal tie bar becomes 0.75 inch. From Figure 43, then

change in diagonal distance due to backlash = 0.75 inch.

Hence horizontal movement at the top of the cell is

1.414 × 0.75 inch = 1.06 inches.

For a seven-tier column, and assuming that all cells in the tier deform by the same amount when strained

sway at top = 7 × 1.06 inches ≈ 7.5 inches.

This would of course put considerable strain on the bolted joints throughout the column, but would give a total range of sway of about 15 inches. This figure may be compared with the figure given by the painter of about 2 to 3 inches just after completion of the bridge.