Construction of piers

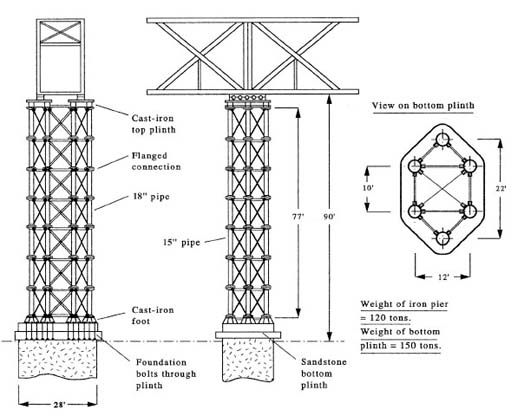

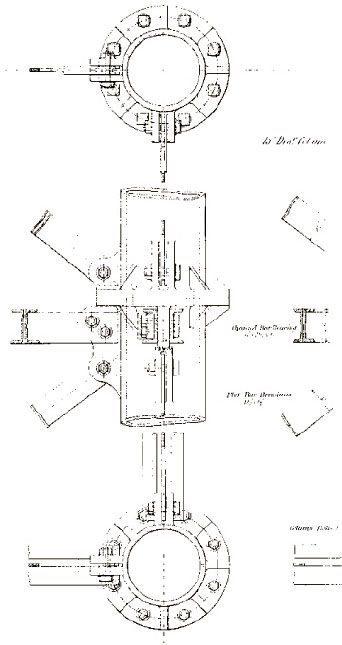

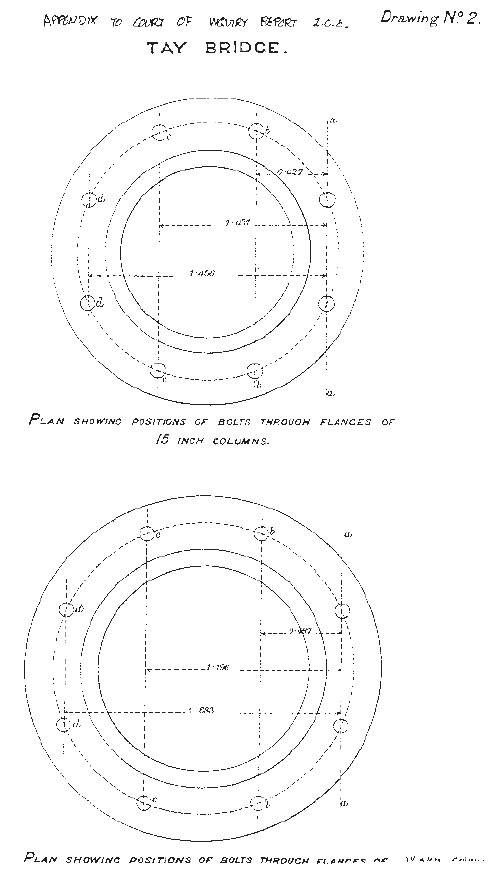

The dimensions and detailed construction of the cast-iron piers are shown in Figure 15. A single pier consisted of six columns of cast iron tied together by struts, bars and rods made from wrought iron. Each pier in the high girders section was built up by bolting together seven flanged cast-iron columns, giving seven tiers. The ends of the flanges were fastened together with eight 1.125 inch (1⅛) wrought iron bolts as shown in Figures 16 and 17, below.

The four columns, forming a rectangle in plan view (Figure 15), had an outside diameter of 15 inches and a wall thickness of 1 inch. The two outside columns had a diameter of 18 inches as shown in Figure 16.

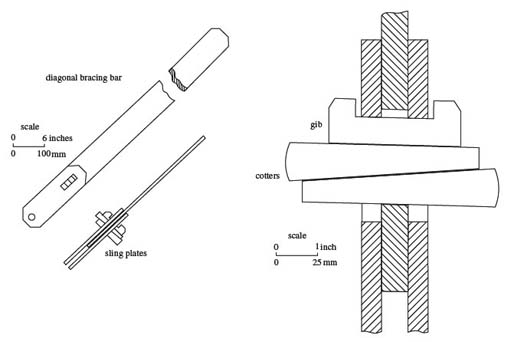

The bracing bars were secured to lugs cast as one with the column. The horizontal bars (referred to in this unit as struts) were made from channel section wrought iron and were secured at each end with two wrought iron bolts. The diagonal bars (referred to in this unit as tie bars) were made from iron flats with a cross-section of 4.5 × 0.5 inches.

Each diagonal tie bar was held by a 1.125 inch bolt at one end and was jointed into two sling plates at the other. The sling plates were attached by another 1.125 inch bolt going through 1.25 inch (1¼) holes in the lugs. The tie bar could then be tensioned at the joint by two cotters (opposed wedges) hammered into a slot that also housed a gib (metal pad), as shown in Figure 18.

As a pier was erected, the inside of each column was filled with Portland cement, apparently to protect it against corrosion. The total weight of a pier complete with cement filling, bars and top plinth was about 120 tons.