4.1 What is manufacturing?

Manufacturing is a very broad activity, encompassing many functions – everything from purchasing to quality control. Shortly we will start to look at some of the main manufacturing processes used to convert materials into products. But before doing this it is worth touching on the relationship between manufacturing processes and the manufacture of products.

To consider manufacturing as a whole we clearly have to look beyond specific sets of materials and processes that lead to single products. One way of doing this is to adopt what is known as a 'systems approach'. I am not going to do so in any depth here. There simply isn't enough space in the course. But a short overview should give you a taste for how viewing activities as 'systems' is a useful technique for organising information about them and providing a more structured way of managing them.

Looking at manufacturing as part of a broader 'production' system provides a way of identifying which factors, whether internal or external, are important, and so aids decision-making about choosing a particular manufacturing process in a particular situation. Sometimes the choice of which material and which process to use will not be trivial. Factors such as consumables needed in the manufacturing processes, the amount of scrap produced, the speed of the process, the energy required, and so on, may all need to be considered in order to make a sensible decision about the best way of making the final product.

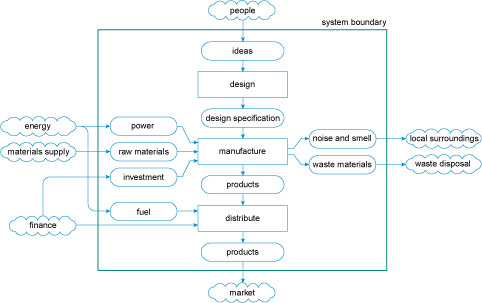

Look at Figure 53. Down the centre of the diagram you will see a flow chart of production from design to distribution, with activities in rectangular boxes as before. I have left out the diamond-shaped decision boxes but added boxes with rounded corners for the inputs to each activity and the outputs from them. This is a very simple systems diagram – another modelling approach to add to the ones you have already met in the course.

When modelling systems, it's important to draw a system boundary around those activities that are being modelled. That then allows us to leave activities outside the boundary in the system environment. Those things we leave outside the system, in the environment, are generally drawn inside clouds. The arrows in the diagram are showing flows – flows of resources, such as power, or the flow of ideas involved in the design process. The resource moves from one box to the next on the diagram.

Figure 53 is an example of a process flow diagram. It tries to describe the whole activity of manufacturing a product, from the initial idea through to delivery of the product to the customer. A key message from such a view of manufacturing is that design and manufacturing are not separate activities but are intimately connected in the production system.

That is where I am going to leave this approach to modelling a production system for the moment. Before that, I need to introduce you to the vast range of methods used to transform materials into objects.