2.3 Prototyping and improving

In Ritchie's first prototype design, which is called P1 for short, the rear wheel hinged forward in its own plane from the lowest point of its triangular support structure, i.e. the wheel did not move sideways for folding. The front wheel of P1 also moved (almost) in its own plane underneath the bicycle to sit alongside its partner; in this case some sideways movement is needed to ensure that the front wheel sits next to the rear one, rather than just bumping against it at its hinges. To achieve this, the front wheel needed a complex, skewed hinge to move it the few centimetres sideways so as to clear the rear wheel and chainwheel.

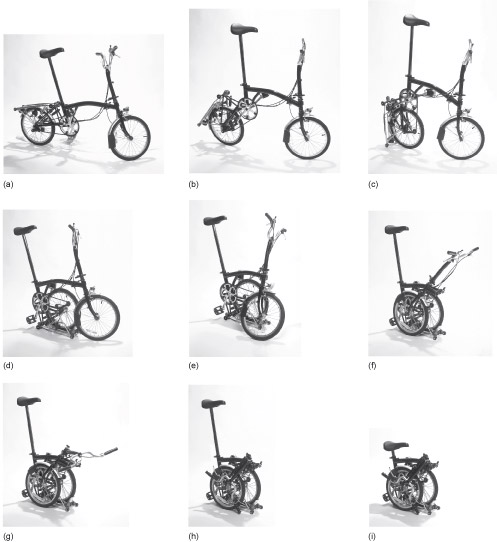

As well as moving the two wheels to the centre it was necessary to move the saddle, together with its pillar, and the handlebars into the same space. The seat pillar telescoped to get the saddle into the packing space, which has the advantage that saddle height adjustment and packing are accomplished by the same mechanism. The telescoped seat pillar slid down behind the hinged rear wheel, so locking it in place, an important feature that survived the transition from prototype to production. Figure 26 shows a modern version of the cycle being folded.

Ritchie was driven by a search for 'the ultimate in compactness' when designing and building his first prototype P1, which was a platform for various design ideas. The chainwheel and the saddle competed for space in the folded package, so Ritchie tried to move the chainwheel away from where the saddle needed to be, into the corner of the side elevation rectangle.

It was too complicated, I gave up an inch when that idea was dropped.

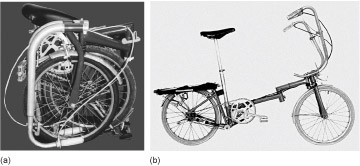

In the picture on the left of Figure 23 you can just see what was happening in this prototype where the saddle and the chainwheel were competing for space – look in the top left-hand corner and you can see the saddle just above the chainwheel behind the rest of the bike in the folded package. Compare this with the later production design in Figure 22 where the saddle and chainwheel are kept apart and Ritchie gave up his 'inch' to move the design forward. P1 used 18-inch wheels, then common on children's bicycles. The main tube of the frame was lower than the production model and the bicycle was not stiff enough. Bowden cables (i.e. those used for bicycle brakes and gear shifts) linked the front and rear wheel-folding mechanisms.

For prototype P1 the problem with the frame was that it was deflecting too much under the load applied to it: one solution to the problem would be to use more material, to make the tube thicker walled or larger diameter. An alternative is to change to a material that is inherently stiffer. The material property related to stiffness is called the Young's modulus. Two components with identical dimensions will show different stiffness if they are made from steel and aluminium, say. The Young's modulus of steel is about three times that of aluminium, so it will make a stiffer component. Indeed evaluation takes place throughout design so that designers are checking all the time about whether their proposal will work and deliver what a customer needs and expects.

Ritchie is a regular bicycle commuter in London, so he tests designs and design changes routinely and expertly. He was pleased with the realisation of the basic design concept in the first prototype:

I had demonstrated that the design concept could result in a compact folding bicycle.

Ritchie also uses the expression 'good luck rather than design' to describe unpredicted advantages of his conceptual design solution.

Activity 10 (self-assessment)

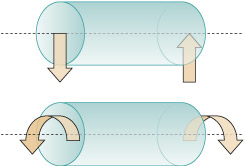

The main frame of a bicycle is essentially a hollow tube. The tube is hollow to reduce mass (removing material from the middle of the tube reduces the stiffness, but not critically, whilst reducing the mass significantly). Suggest two ways that the frame can be made stiffer.

Answer

This is a simple question about the shape of the tube. First, you could make the tube a larger external diameter whilst keeping the thickness of the tube the same. The bigger tube has more material (because it is a larger radius but the same thickness) but more importantly the metal material is further away from the centre line of the tube. Material further from the centre makes it stiffer if you try to bend the tube or twist it – see above figure. Second, you could make the tube from a stiffer material, that is, with a higher Young's modulus which you will explore later. Steel tube would generally be stiffer than aluminium alloy and a titanium alloy stiffer than an aluminium one, while carbon fibre might be stiffer than many metals. Bicycle tubing is a subtle design issue. A designer needs to balance competing factors: it should be both light and stiff, as well as strong enough to avoid damage and deformation. This indicates a vital difference between strength and stiffness that we will come to later in this course.

Activity 11 (exploratory)

In this activity you will take a closer look at another folding bike and compare its frame with the Brompton.

I suggest that you look at Airframe (Figure 21(b)) or Dahon (Figure 21(d)), you may want to do some research on the Web. Compare the frames in terms of:

- configuration

- location of hinges.

Discussion

I have chosen the Airframe bike (b) in the figure below, taken from the company website. Look at the frame configuration, which is very different to the Brompton. It is essentially three rigid triangular structures rather than one strong 'beam' as seen in the Brompton (a) in the figure below. It has smaller radius tubes with joints that can be rotated to fold the bike. It is probably not as compact as the Brompton. It is constructed from aluminium alloy tubing jointed at saddle, bottom bracket and handlebars using special purpose joints. The steel cross brace from saddle to front wheel holds the whole structure rigid and when disconnected allows the whole bike to fold.