Aquaculture waste - generation and current management

One of the most critical challenges that humanity currently faces is the production of enough food for an expected population of 9.6 billion people by 2050. Global per capita fish consumption has more than doubled in the last fifty years, in line with increasing demand by a growing, wealthier, and more urbanised population.

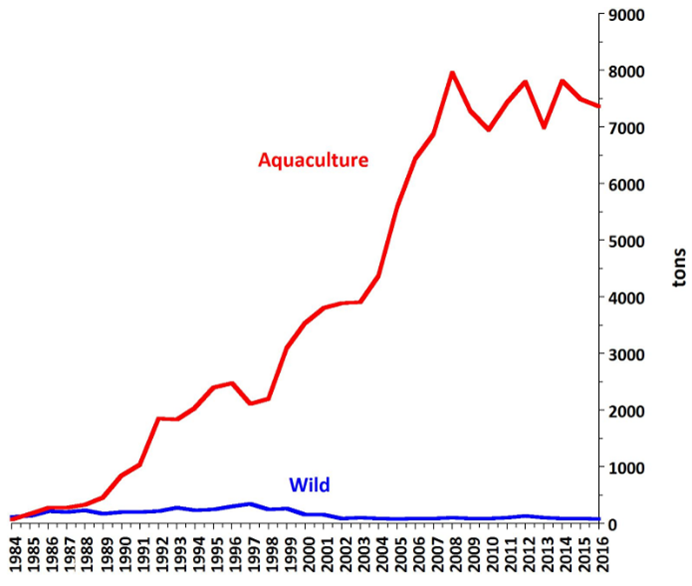

Up to the 1980s, demand was mainly met by increased wild capture, but aquaculture has rapidly closed the gap, equating production and consumption with fisheries in the last years. The production of aquaculture fish around the world achieved 80 million tons in 2016, supposing 48% of the total fish captured, transformed, and marketed. In some cases, for example turbot (Scophthalmus Maximus), increased production in Europe, from 1984-1986 at the beginning of farming activities of this species. The increase in the period 1984-2016 showed a global sigmoid profile (Figure 2): exponential between 1989 and 2007, and with a stationary phase with ripples from 2008 to 2016. The balance between wild-aquaculture production, as a percentage, moved from 100%-0% to 1%-99% in 30 years.

Figure 2. Production of aquaculture and wild turbot in Europe for 1984-2016. Source: Redrawn from La Acuicultura en España,

APROMAR (2018)

Although in many countries fish species are conventionally marketed as whole fish, fillet presentations are growing year after year around the world. The procedure of filleting (headless, gutted, etc.) generates a huge amount of by-products. In many cases, this residual biomass accounts for about 40-60% of the total fish weight and must be managed to avoid environmental health problems in fish farming plants or in fish processing food companies. For European salmon, the most abundant species farmed in Europe, the different by-products obtained in the filleting process are heads (10%), frames and bones (22.5%), trimmings (2%), and viscera (12.5%). Similar percentages are also found in rainbow trout, sea bream, and seabass processing.

Those fish by-products are commonly used for the production of silage or fish meal and fish oil. Silage is a liquid or dried product resulting mainly from chemical hydrolysis, prepared by combining inorganic acids –such as formic or phosphoric acids– to lower pH value to 4 in order to inhibit microbial growth and avoid spoilage. When viscera are present in the fish substrate endogenous enzymes, included in the pancreas or in the pyloric caeca, it can be used as a biocatalyst for the production of silage. On the other hand, when lactic acid bacteria is employed as a reagent for the fermentation, hydrolysis, and stabilisation of fish substrate, the product obtained is called biosilage. These can be applied as liquids or can be dried by freeze-drying, spray-drying, or fluidised bed drying.

Fish meal is a material mainly proteic (between 50-75%, w/w) obtained from the crushing, thermal, and drying processing of different fish substrates or fish residues. It also contains a variable level of inorganic fraction (ash) depending on the number of bones present in the waste and the type of separation process. Fish oil is also recovered concomitantly with the production of meals by cooking, pressing, and centrifugation of fish waste. Its quality in terms of omega-3/omega-6 ratio is a function of the fish species processed. Fish meal is a basic ingredient in aquaculture feed formulation, and its commercial value is directly proportional to the concentration of protein.

Comparatively, fish silage production is simpler than fish meal since the equipment necessary is cheaper, and also the energy demand and time consumption are lower than fish meal plants. In general, fish meal production is more efficient and viable when the volume of waste to be treated and the size of the processing plant are increased. However, fish silage units are more flexible and more adequate to be implemented in locations where the volume or seasonal availability of fish by-products is not enough to justify operation in a traditional fish meal plant. Nevertheless, silage contains more than 60% water, forcing an intense concentration and/or exhaustive drying if this material wants to be marketed far from its place of production.

Although fish meal production is a well established and economically very profitable business, other valorisation processes, in line with circular economy principles and based on the concept of marine biorefinery, have been developed for the generation and extraction of valuable products such as fish protein hydrolysates, glycosaminoglycans, bioapatites, marine peptones, collagen, etc.