Processes to produce gelatins from skin fish waste

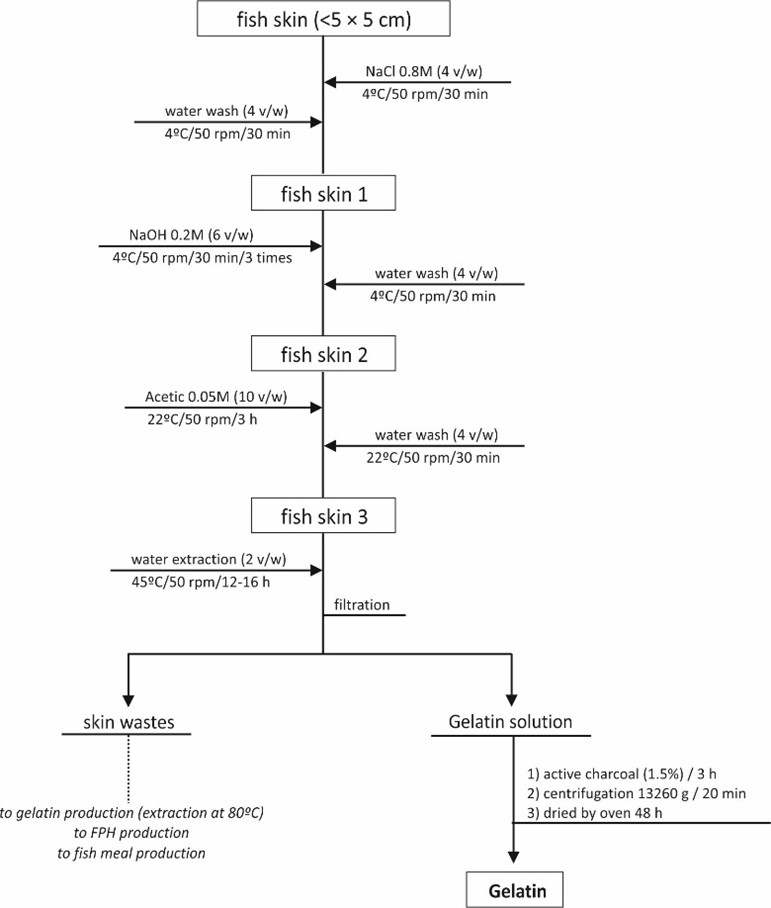

The protocols developed to isolate fish gelatin are mainly based on pre-treatments of skins with different alkalis and mineral and organic acids. The alkaline step hydrolyzes and removes non-collagenous proteins without degradation and loss of collagen, and the acid wash prepares the skin for minimising the loss of collagen for the subsequent thermal extraction of gelatin.

The ratio (S:L, skin: reagent liquid) applied to the soaking step are commonly higher than 1:6 and the different reagents employed are NaOH and H2SO4 but Ca(OH)2, NaCl, H3PO4, butyl alcohol or even acetic, lactic, and citric acids (Figure 1). The final extraction of gelatins is almost always performed with hot water at 40–80ºC, in one or two steps, for several hours (between 2–16 h). Enzyme-assisted treatment or high-pressure application for gelatin extraction from the skin is moreover indicated, in some cases, for improving the chemical properties of gelatin obtained. Purification of aqueous gelatin solutions is subsequently applied, using membranes and/or adsorbents, before the drying step. Depending on the commercial presentation of the final gelatin product, a milling stage can be also needed.

Figure 1. Flowchart defined for the production of fish gelatin using a combination of NaCl, NaOH, and acetic acid treatments together with thermal extraction.