Bacterial fermentation on marine peptones from aquaculture wastes

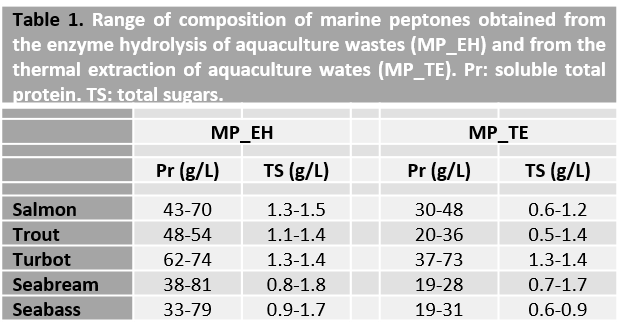

All waste generated in the industrial processing of the most important aquaculture species in Europe (heads, viscera, trimmings together with frames of turbot, salmon, trout, sea bream, and seabass) were studied in the GAIN project as sources of marine peptones prepared by two protocols: thermal extraction (MP_TE) and exogenous enzyme hydrolysis (MP_EH). The concentrations of proteins present in peptones varied from 33 to 81 g/L for peptones from enzyme hydrolysis and 19 to 73 g/L from the thermal procedure (Table 1). For all species, the yield of protein recovered from EH was higher than those reached with TE. The average molecular weights of the peptides present in EH were around 900–1800 Da with 5% of peptides larger than 3 kDa. In the case of TP, those values ranged mostly between 50–640 kDa since no specific protein hydrolysis was applied.

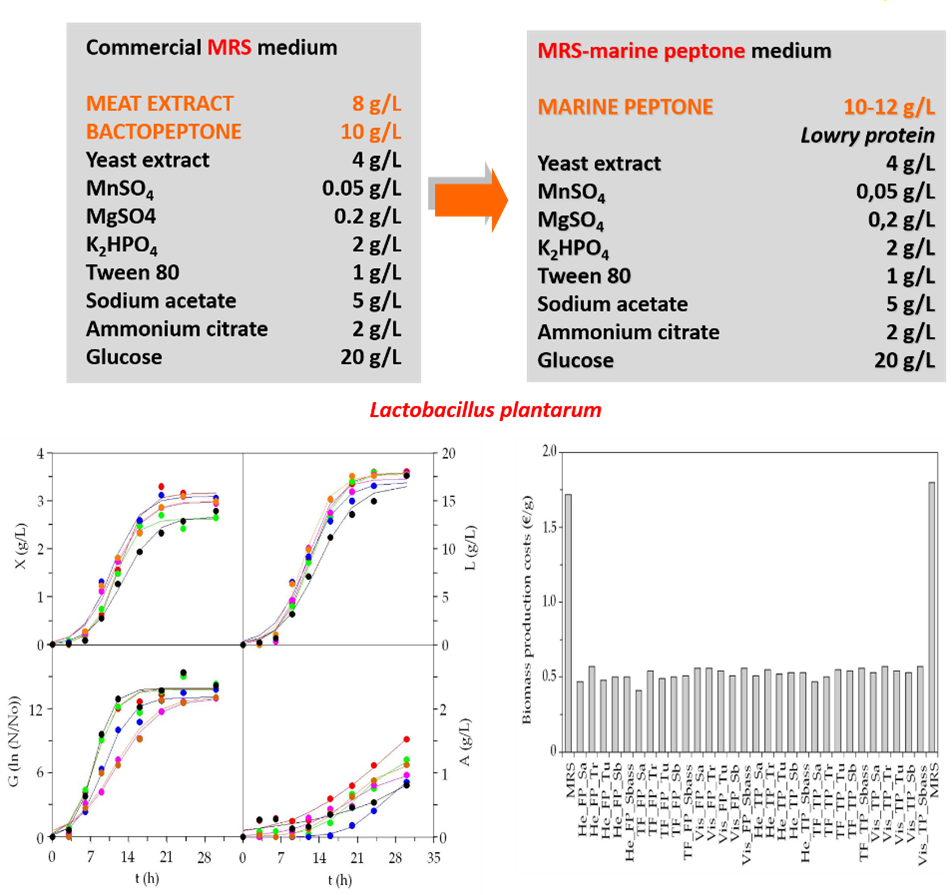

Focusing on the case of LAB, the low-cost media that we have formulated with these marine peptones are a reproduction of the Man-Rogosa-Sharpe (MRS) complex medium, in which the corresponding peptone from aquaculture was incorporated at the same concentration of Pr of the commercial peptones replaced (meat and bactopeptone) (Figure 2, top). Two LAB of technological interest (Lactobacillus plantarum and Lactobacillus brevis) were selected for the evaluation of these new substrates and, in all cases, the fermentations were carried out in batch cultures for 32-36 h in Erlenmeyer flasks of 300 mL (loaded with 180 mL of culture medium) at 30ºC, 200 rpm of orbital shaking and without the addition of oxygen.

The results revealed that: (i) bacterial growths, biomass as dry weight and viable cell production, were similar or higher in alternative marine peptone media than those found in MRS media (see Figure 2, bottom, as an example of L. plantarum cultivated on MP_EH from fish farming heads); (ii) the productions of the two main metabolites of LAB, lactic and acetic acids, were also identical or larger in the fermentations on MP alternative media; (iii) the cost of production for both bacteria, comparing MRS and MP, were reduced between 3-4 times for biomass, 2-4 times for cell viability and 2.5-3 times for lactic acid.

Figure 2. Top: Composition of MRS commercial medium and marine peptone-MRS medium. Bottom-left: Kinetics of the LAB Lactobacillus plantarum fermentation showing productions of biomass (X), lactic acid (L), acetic acid (A), and viable cells (G) on peptones from hydrolysis heads and MRS-control. Bottom-right: Comparison of biomass production costs for L. plantarum in the alternative media formulated with marine peptones and in the commercial MRS medium.

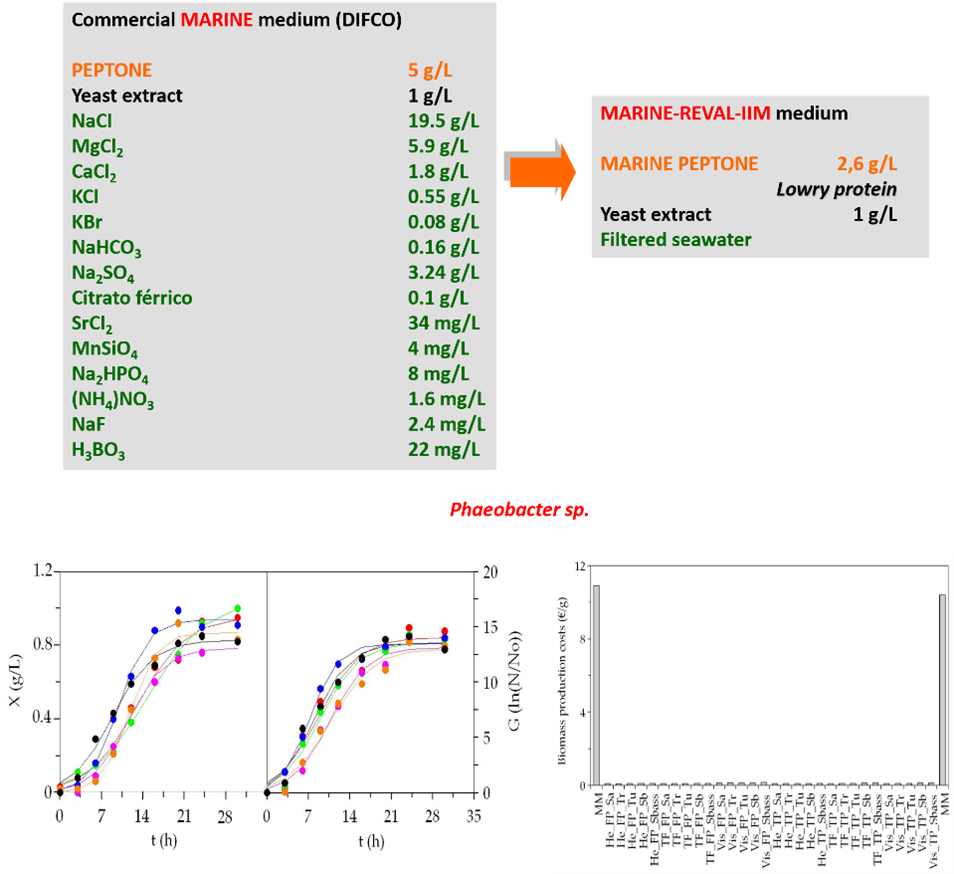

PMB grows in a specific broth, marine medium, specially designed for the culture of bacteria isolated from marine environments (Figure 3). However, this medium is too expensive and the development of a cost-effective medium is fundamental for a continuous and sustainable supply of massive biomass and viable cells of PMB to aquaculture plants and hatcheries. It is composed of multiple mineral salts, simulating seawater, a low concentration of yeast extract, and a generic peptone. Two PMB (Phaeobacter sp. and Pseudomonas fluorescens) were chosen for culture, performing them in 300 mL-flasks (with 150 mL of medium) at 22ºC/200 rpm/without O2-supplementation.

The kinetics of PMB growth

on new marine media including MP showed the conventional sigmoid profiles for bacterial

growths and led to the following global conclusions: (i) similar or higher

maxima growths, both for biomass and viable cells, were observed on low-cost

marine media in comparison to those reported by commercial medium; (ii) for both PMB,

the reduction of production costs were lager than 70 times for biomass and 60

times for cellular production. Figure 3-bottom displayed an example of the

cultivation of Phaeobacter sp. on

MP_EH from aquaculture heads.

Figure 3. Top: Composition of Marine commercial medium and marine peptone-Marine medium (Marine-REVAL-IIM). Bottom-left: Kinetics of the PMB Phaeobacter sp. fermentation showing productions of biomass (X) and viable cells (G) on peptones from hydrolysis heads and MRS-control. Bottom-right: Comparison of biomass production costs for Phaeobacter sp. in the alternative media formulated with marine peptones and in the commercial Marine medium.