Collagen extraction process. By-products from aquaculture fish for collagen production

The processing of aquaculture fish may result in

by-products, depending on the degree of processing. However, the

common practice for both fishery and aquaculture industries is to mix the

different by-products generated with processing, i.e., heads, viscera,

trimmings, and frames, and use them as a raw material for the fish meal industry

(Figure 14).

Figure 14. Fishery by-product valorization for fishmeal production

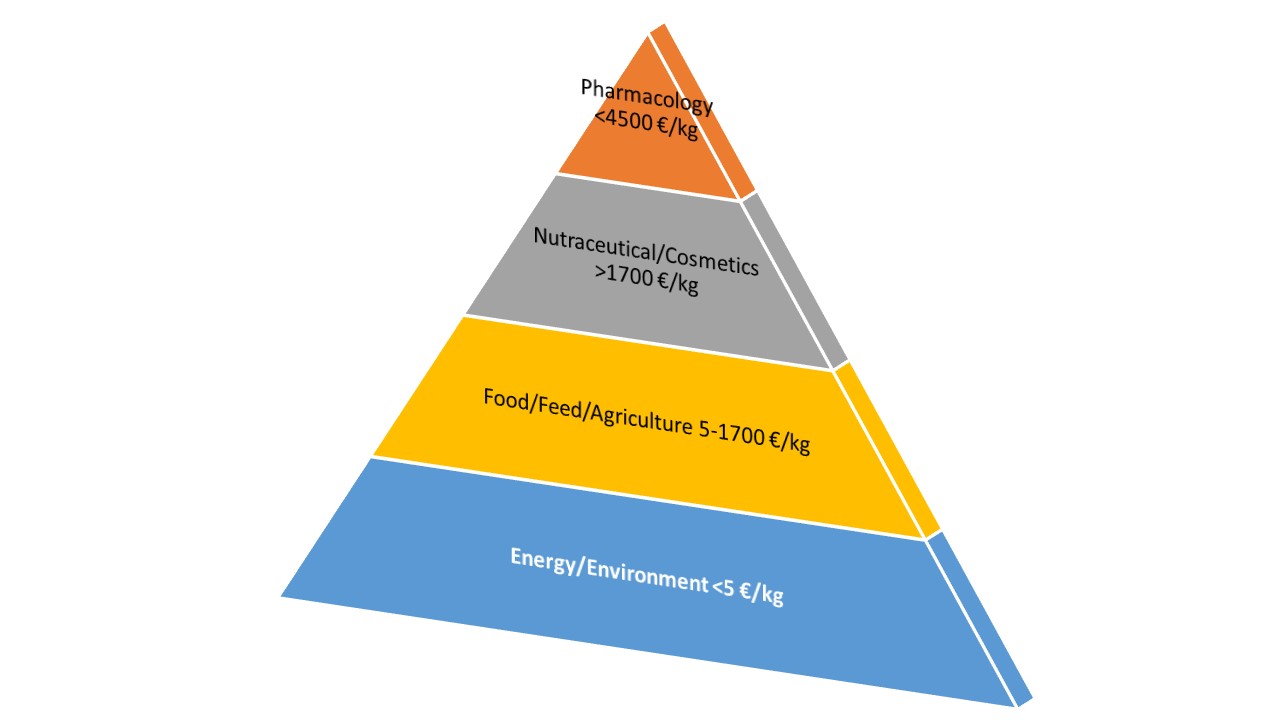

Some published works have shown that this is a low-value product and, if separation and preservation of by-products are performed, higher added value products could be obtained (8). By-products can achieve higher valorisation added value depending on the target industry: lower prices are achieved if they are used in the food, feed, and agriculture compared to the value obtained in the nutraceutical, cosmetic, or pharmacology sectors9 (Figure 15).

Figure 15. Valorization strategies and added value. Adapted from Barbier et al. 2019 (7).

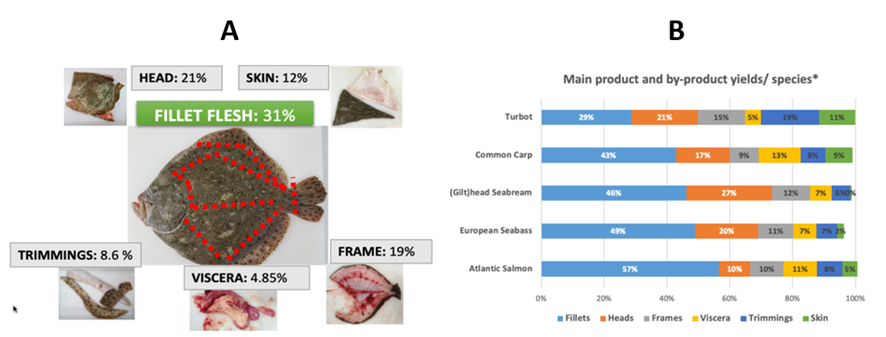

Fish exhibit

different by-product yields. In the case of turbot (S. maximus) as shown

in Figure 16, the flesh yield is the lowest, compared with other

aquaculture species, such as Atlantic salmon (S. salar).

Figure 16. By-product yields for turbot (S. maximus) (A). Comparison of by-product yields in different aquaculture species (B).