What steps and variables must be evaluated for optimising the production of FPH?

The first stage to execute, after substrate homogenization, must be the study of the experimental conditions that maximise the process of hydrolysis of fish wastes. This entails knowing the influence of the most relevant variables that affect the proteolytic activity of the protease employed for the digestion of the fish wastes. The independent variables to control are pH, temperature (T), solid: liquid ratio (r(S:L)), [protease], agitation, and time of hydrolysis. The dependent variables (responses) to determine are the degree of hydrolysis, total soluble protein, the yield of digestion, bioactivities, etc.

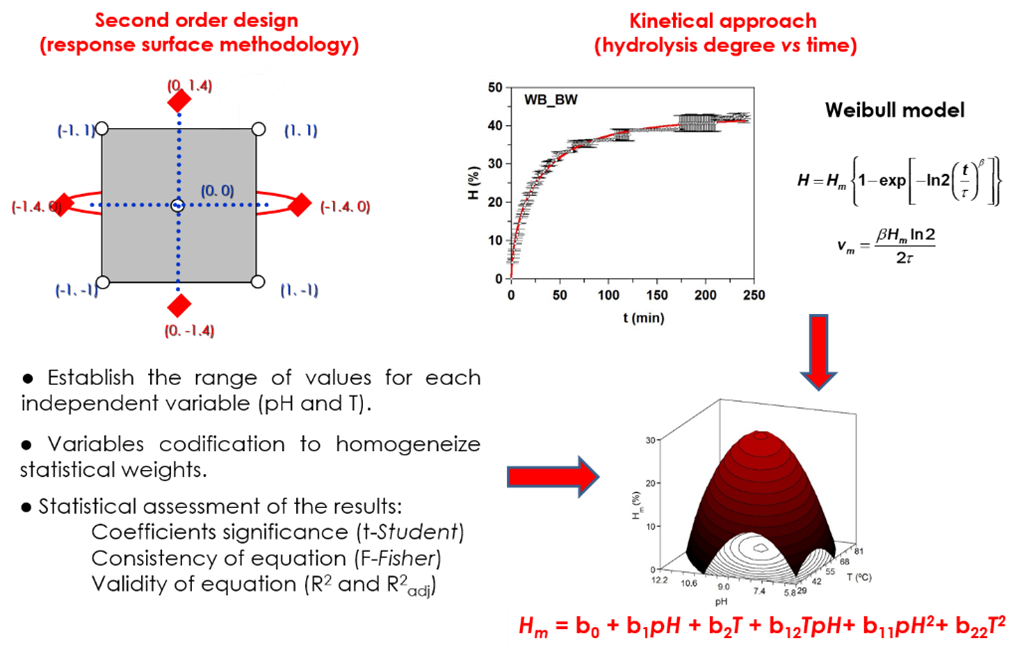

Different experimental designs, methodologies, and statistical approaches can be applied to optimise fish biomass proteolysis such as neural network, multivariable analysis, Taguchi robust design, Latin squares, response surface methodology (RSM), etc. From all of them, RSM employing Box-Behnken designs is one of the best options in order to reduce the number of experiments needed for optimization and to obtain robust predictive mathematical models (polynomial equations) that enable the search of the values of the studied variables that maximise the responses (Figure 2).

Figure 2. Representation of the mathematical methods applied for the optimisation of enzyme hydrolysis of fish wastes

In the case of aquaculture wastes, a strategy of optimisation to consider is:

1) to study the simultaneous effect of pH and T by a second-order factorial design combined with a kinetic approach -–for controlling the time-course of the hydrolysis—maintaining agitation, r(S:L) and [protease] constant

2) after responses maximisation, pH and T remain constant in optimal values and [protease] individual effect is studied

3) to scale-up FPH production at 5 L reactor under the conditions obtained from previous stages to validate those optimal values; 4) to scale-up FPH production at 300-500 L reactor under optimal conditions

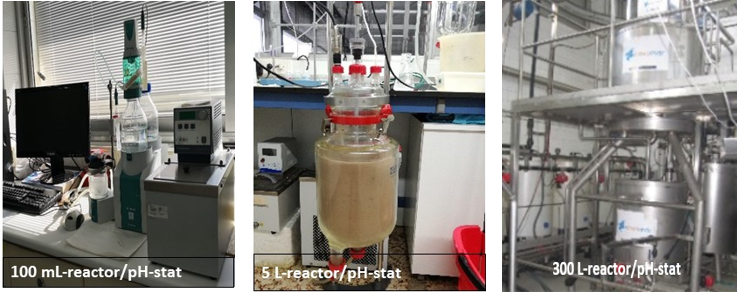

The pH-stat thermostated reactor is the perfect equipment for FPH production. It should be equipped with a system of agitation, pH measurement, and control by means of a pH sensor connected to a pump for dosing of acid or alkali, control of T, and online recording of pH, T and reagents consumption (Figure 3).

Figure 3. pH-stat reactors of different working volumes, 100ml, 5L, and 300 L

Performing waste proteolysis in the pH-stat reactor, the determination of the degree of hydrolysis can be easily implemented and continuously monitored. The calculation of the degree of hydrolysis is based on the release of amino acids after peptide bond breakdown with the concomitant decrease of the pH. Thus, the degree of hydrolysis is proportional to the alkalis consumed (Adler-Nissen method).