Production of marine peptones

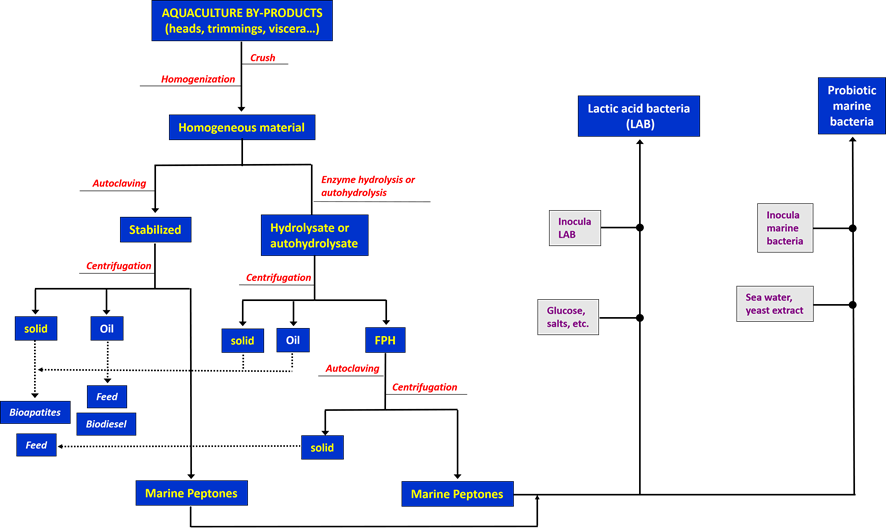

For the production of marine peptones, excluding those obtained by chemical hydrolysis, the process begins with the homogenization (by crushing, grinding,) of fish wastes (Figure 1). For the case of peptones from thermal extraction, this homogeneous material is mixed with water (i.e., (S:L) ratio of 1:1 or 1:2) for autoclaving at 121ºC/15 min in order to improve the extraction of protein-rich liquid together with the sterilisation of peptone. After centrifugation, the solids and oils recovered can be directed for use in feed, bioapatite, or biodiesel approaches, and the marine peptone is ready for inclusion in culture media.

Figure 1. Flowchart defined for the production of marine peptones useful as an organic nitrogen source for the growth of lactic acid bacteria or probiotic marine bacteria.

For the production of marine peptones by enzyme hydrolysis, when commercial/exogenous protease is used, the production process is quite similar to that described earlier for the FPH production, that is, enzyme digestion of these substrates under controlled conditions, separation of non-digested materials, and recovery of oils from liquid hydrolysates by centrifugation-decantation. The difference between marine peptone and FPH is that the enzyme deactivation process is carried out in an autoclave (at 121ºC for 15 min) to:

1) deactivate the enzyme

2) kill the possible presence of microorganisms in the hydrolysates and

3) help in the flocculation and removal of insoluble proteins. Liquid marine peptone can be used directly for submerged fermentation of bacteria or dried, by spray-drying or freeze-drying, as a usual format for marketing.

In the case of utilising the proteolytic activities present in the digestive system of fish, they are put in contact with the rest of fish substrates diluted in water ((S:L) ratio of 1:1), the pH is adjusted in the range of 7-9 (searching optimal conditions for alkaline proteases) or 2-3 (for acid proteases) and the mixture is incubated at 25-40ºC for 3-6 h under 200 rpm of orbital shaking. After autolysis, the hydrolysate is processed as in the previous option of an exogenous enzyme to obtain the final marine peptone. The hydrolytic activity of enzymes from fish viscera depends on the treated species, its physiological condition, the seasonal variation, and the operating conditions applied. Although it is an economically interesting alternative, it is limited by factors as its low reproducibility and difficult control, reaching productive yields lower than those found using exogenous protease.

Two types of bacterial groups are especially interesting to evaluate the validity of marine peptones and to implement a bioconversion procedure: lactic acid bacteria (LAB) and probiotic marine bacteria (PMB). LAB are Gram (+) bacteria claimed as fastidious in terms of nutritional requirements for its growth (need of complex medium with a varied number of peptones as MRS medium) and are also one of the most important industrial microorganisms due to their probiotic and technological properties: they are dairy and sausage starters, producers of lactic acid, bacteriocins, exopolysaccharides, cheese, yogurt, beverages, etc. PMB are a group of Gram (-) that habit in seawater and have shown to be beneficial for the reduction of mortalities and improving health in the diseases of fish farming.