7.4 Wear

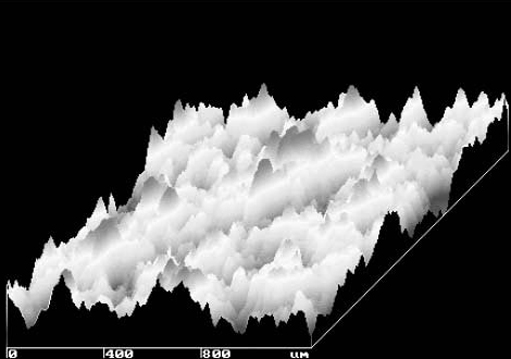

Wear can be defined as the unintentional, progressive loss of material from a surface. All surfaces are rough at the microscopic scale. Figure 55 shows the trace taken of a surface using a stylus profilometer (this is like dragging a record player stylus across the surface of a material and measuring the vertical deflection). The surface has considerable variation as can be seen from the peaks and troughs. These peaks are termed asperities and these are important in wear as hard, sharp asperities may plough into a softer material. In addition, when two surfaces are touching, it is the tips of the asperities that contact rather than the overall surface, so the true contact area between the surfaces is a lot smaller than you may think. This means that the friction can be controlled by how the asperities bear the load and deform. It also influences the way in which the materials wear.