1.3.2 Human/product interaction

The balance of properties needed in a particular product varies enormously, depending on the exact duty that product will perform in service, the environment in which it will operate, and the way it will interact with the user or consumer. The last factor has assumed much greater influence in product design as competition between different manufacturers sharpens the perception of quality in users’ eyes. The study of human-product interactions is variously known as human factors or ergonomics. The academic subject seeks to isolate those ways in which machine or product and the user interact, and how product design influences the effectiveness, or efficiency or safety of the product concerned.

So what polymer properties are important here? One argument might point towards the generally low stiffness of most polymers and their products, not dissimilar in fact to that of the users’ hands or skin. Human skin is mainly composed of a natural polymer, the protein elastin, which is an elastomer and hence highly extensible and of low intrinsic stiffness. So external surfaces of products which must be handled are more compatible when the material is polymeric. Polymers also have low thermal conductivities, so such surfaces will not feel cold, and the user will be able to hold polymeric products longer and with greater ease than in the case of metals, for example. Plastic or rubber handles for tools are thus the preferred materials, and. in a way, the power tool enclosures examined above are really just an extension of the handle to encompass the whole tool.

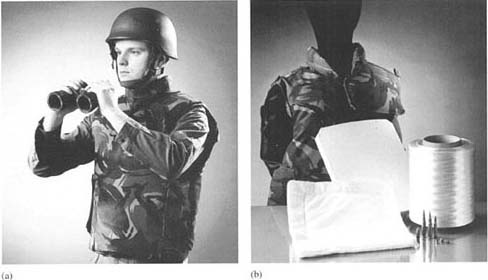

In a similar vein, polymeric textiles must be highly flexible to accommodate movement of the human body, so are composed of fibre assemblies where the stiffness is lowered further by the small diameter of the individual fibre. Low density and low thermal conductivity reinforce the selection of polymers for this product specification. Advances in polymer technology in the last few decades have further enhanced the profile of properties expected from polymeric materials however. Thus metal chain mail has in the past been the main way of protecting the human body from high external stresses, such as ballistic forces. Many polymers can now be processed into fibres of very high intrinsic stiffness, approaching if not exceeding that of inorganic materials. Such high-performance fibres can be woven into textile fabrics and they offer substantial ballistic protection, so can be used for bullet-proof jackets and rip-resistant clothing for sports competitors (Figure 11).