5.2.1 Elastic and viscoelastic behaviour

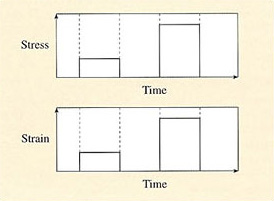

When an elastic (not elastomeric, or long range elastic) material is stressed, there is an immediate and corresponding strain response. Figure 43 illustrates this by showing schematically the strain response to a particular stress history. Note that when the stress is removed the strain also returns to zero. So in a perfectly elastic material all the deformation is returned to the forcing agency. If this energy had not been stored elastically then it would have been dissipated as either heat or sound. Tyre squeal and the heat build-up in the sidewalls of car tyres are good examples of such dissipation.

If the material is linear and elastic then the applied stress σ directly proportional to the strain ε. Then, for simple tension,

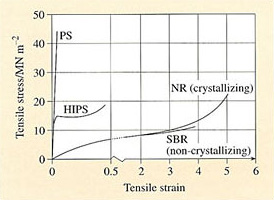

where E is a constant known as Young's modulus, and is considered to be a property of the material. For polymers, due to time-dependence and nonlinearity, E is not a constant and the term tensile modulus is used to reflect this. The stress-strain curves for PS, HIPS and two types of rubber are shown in Figure 44. While polystyrene apparently obeys Hooke's law (Equation (27)), HIPS yields and necks before failing. By contrast, rubbers exhibit long-range elasticity and fail only at many hundred per cent strain.

So some plastics like HIPS yield, but others fracture in a brittle manner like polystyrene. Rubbers do not yield, but at high strains some of them crystallise and hence stiffen. When the stresses are removed from a polymeric material before fracture, the strain recovery path is not necessarily identical to that of the loading part of the deformation cycle. So energy must have been dissipated during the deformation of such materials – another indication of deviation from perfect elasticity. Both the deformation and the subsequent recovery are time-dependent, suggesting that some part of their behaviour is viscous. In fact solid polymers show a combination of elastic and viscous behaviour known as viscoelasticity. The degree of viscoelasticity is strongly dependent upon the temperature of test and the rate at which the polymer is deformed, as well as such structural variables as degree of crystallinity, crosslinking, and molecular mass.